Product Features

Subversive heat exchange design, overall performance improvement

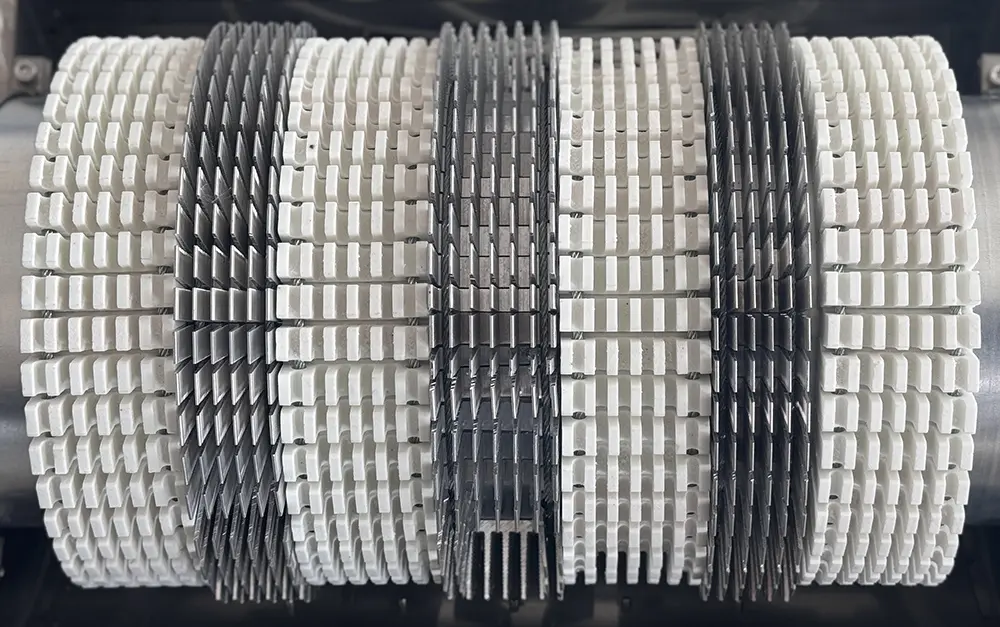

Large heat exchange surface area: Annular aluminum heat sink + corrugated rib surface structure, compared with traditional casting cooling elements, improve the heat exchange area and heat transfer efficiency per unit time.

Structure innovation and reliability assurance

All-scene adaptability: Through the flexible connection structure of double stretch cable, the system can be quickly adapted to various diameters of extruder barrels, compatible with vertical, horizontal and other models.

Lean manufacturing concept, significantly reduce the cost

Lightweight modular design: Abandon the complex sand mold casting process of traditional castings, adopt precision processing of aluminum profiles and modular assembly of ceramic components, greatly shorten the production cycle, improve the material utilization rate, and reduce the production cost.

All-scene adaptability: Through the flexible connection structure of double stretch cable, the system can be quickly adapted to various diameters of extruder barrels, compatible with vertical, horizontal and other models.

Structure

Technical Parameter

Voltage |

230V/400V(China), 277V/480V(Germany) |

Wattage |

Max. 6.5w/cm2 |

Working Temperature |

400℃ |

Housing Material |

Stainless steel or aluminized steel plate |

Insulation Material |

Ceramic |

Heating element |

1200℃ Cr20Ni80 |

Power Connection |

Resistant to 500℃ high temperature cables, and connection box |

Single blower air supply power(550W) |

Max. 25cm3/min |

Double blower air supply power(550W) |

Max. 23.2cm3/min |

By Laier Heating TO KNOW MORE ABOUT Laier Heating, PLEASE CONTACT US!

- kangpu@yckp.com

-

No.118, Xinyuan Road, Economic Development Zone, Yancheng, Jiangsu

Our experts will solve them in no time.