Yancheng Laier Heating Technology Co., LTD. : Take you to explore the mystery of casting aluminum heaters into molds

The casting and mold-forming process of Cast Aluminum Heaters begins with the meticulous design of the mold. Technicians, based on the specifications and usage requirements of the heater, use advanced computer-aided design software to precisely calculate the size and shape of the mold, ensuring that the mold can meet the structural and performance requirements of the heater. The precision of the mold directly affects the quality of the heater, so every detail has been repeatedly deliberated and verified.

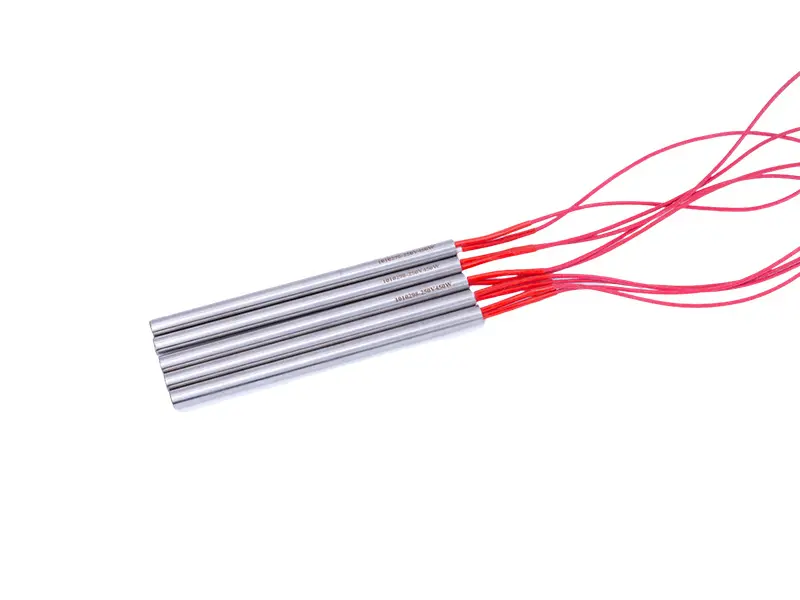

Next comes the installation of the electric Heating Element. The electric heating element is the core component of the heater, usually made of high-quality resistance wire or electric heating tubes. In the mold, the electric heating elements are precisely placed in the predetermined positions and ensured not to shift during the pouring process through professional fixing devices. These electric heating elements can generate heat after being powered on, providing power for the heater.

Subsequently, the melting and pouring of aluminium alloy are the key links in the entire process. In a professional furnace, the aluminium alloy is heated to an appropriate temperature to make it completely melt. Molten aluminum alloy has good fluidity and plasticity at high temperatures, which is a key factor in ensuring the quality of the heater. The operator slowly injects the molten aluminum alloy into the mold, while closely monitoring the pouring speed and temperature to prevent the formation of bubbles and impurities. After the pouring is completed, the mold is placed in the cooling device to allow the aluminum alloy to gradually cool and solidify.

Finally, the Cast Aluminum Heater after cooling takes shape initially, but it still needs to go through a series of fine processing procedures. Technicians will use lathes, milling machines and other equipment to precisely process the surface of the heater, remove excess aluminum alloy, and ensure the dimensional accuracy and surface finish of the heater. At the same time, strict inspections and tests will also be conducted on the heaters, including electrical performance tests, withstand voltage tests, etc., to ensure that each product can meet the high standards of quality requirements.

Yancheng Laier Heating Technology Co., Ltd. ensures that every cast aluminum heater can provide customers with efficient and reliable heating solutions through exquisite craftsmanship and strict quality control. Cast aluminum heaters have been widely applied in multiple fields such as plastic processing, rubber products, and chemical equipment due to their excellent thermal conductivity, uniform heating effect, and long service life. Through today’s popular science introduction, we believe that you have gained a deeper understanding of the casting mold forming process of the casting heater.