Heating/Cooling Integrated System

Product Features

Precise temperature control

Eliminate temperature fluctuations to ensure that PVC raw materials maintain the best molten state during the extrusion process, improving the molding accuracy and mechanical properties of the products;

Energy consumption optimization

Adjust the heating and cooling power as needed. Compared with traditional independent equipment, it saves more than 30% of energy and reduces production costs.

Stable process

3.Effectively suppresses the accumulation of frictional heat, reduces the frequency of maintenance shutdowns caused by abnormal temperatures, and enhances production efficiency.

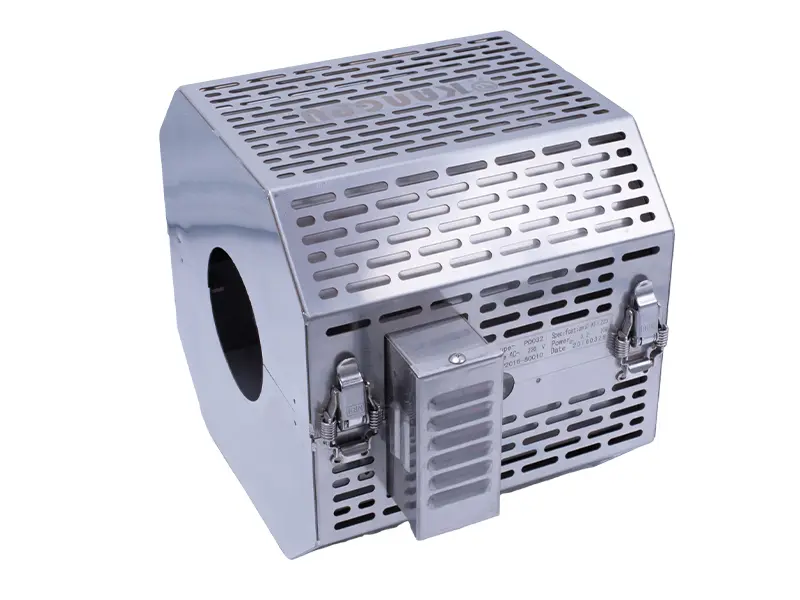

Structure

Depending on the desired performance of the system, the heating function can be achieved by modular elements (ceramic and mica) or cast aluminum/cast copper heaters. The cooling function of the system is carried out using forced and directional air, which is invested in resistors and radiators, usually made of aluminum or copper.

We can design the ratio of heating and cooling surface area according to the heating and cooling power required by our customers. We can provide both single-phase power supply, and three-phase power supply heater and fan.

Technical Parameter

Voltage |

230V/400V(China), 277V/480V(Germany) |

Wattage |

5w/cm2-6.5w/cm2 |

Working Temperature |

400℃ |

Housing Material |

Stainless steel or aluminized steel plate |

Insulation Material |

Mica or ceramic |

Heating element |

1200℃ Cr20Ni80 |

Power Connection |

Resistant to 500℃ high temperature cables, and connection box |

Single blower air supply power |

Max. 27.1cm3/min |

Double blower air supply power |

Max. 55cm3/min |

By Laier Heating TO KNOW MORE ABOUT Laier Heating, PLEASE CONTACT US!

- kangpu@yckp.com

-

No.118, Xinyuan Road, Economic Development Zone, Yancheng, Jiangsu

Our experts will solve them in no time.