Electromagnetic induction heater

Introduction

The electromagnetic induction heater achieves efficient heating by utilizing the principle of electromagnetic induction. It converts 50-60Hz alternating current into 20-25KHz medium-frequency current, generating an alternating magnetic field through the induction coil. The metal heated object generates eddy currents in the magnetic field and heats up due to its own resistance, achieving self-heating. The induction coil generates almost no heat, with a thermal efficiency of over 95%. Compared with traditional heating methods, it heats up faster, controls temperature more accurately, and consumes less energy.

Structure

It is composed of induction board induction coil and control box.

1. Motherboard: Core control unit, responsible for current conversion and parameter adjustment, featuring multiple protection functions such as overcurrent, overvoltage, and over-temperature;

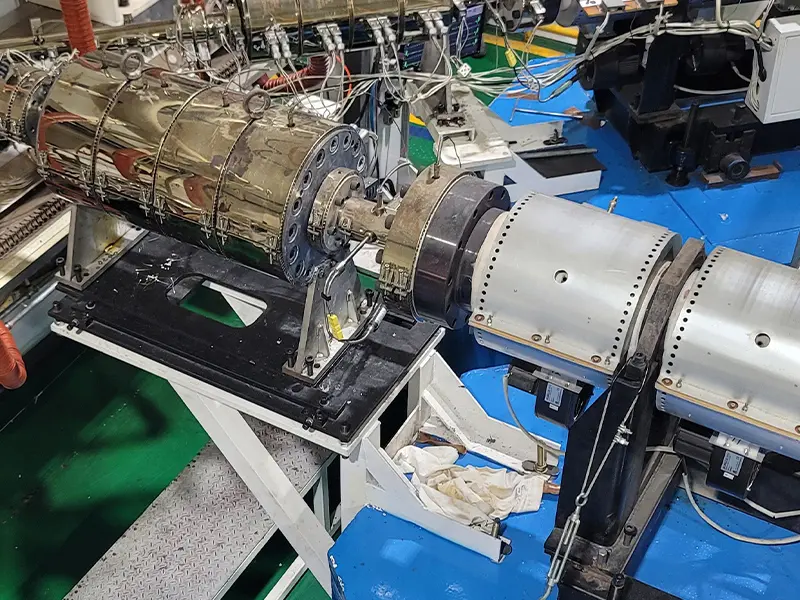

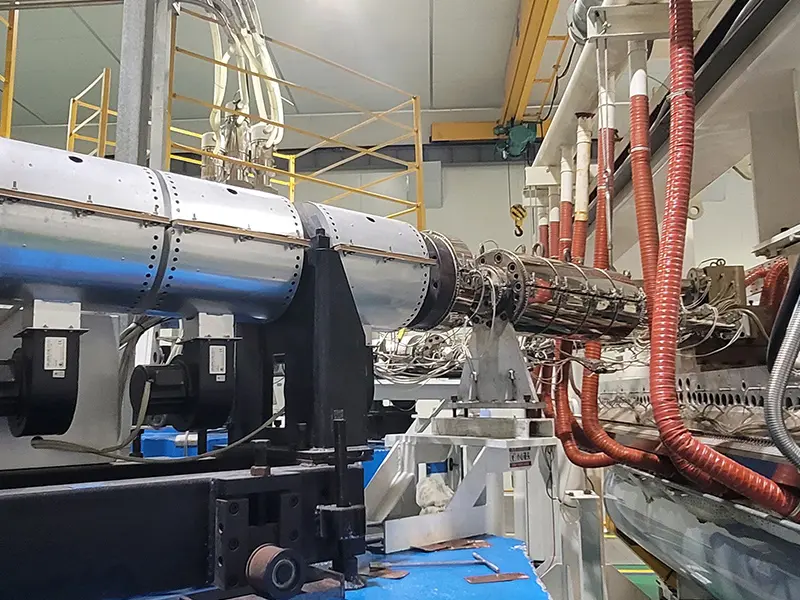

2. Mutual inductance coil: Customized in shape according to requirements, it converts current into a magnetic field and directly acts on the heated object.

3. Control cabinet: Integrates the mainboard and operation interface, supporting visual setting and real-time monitoring of parameters such as temperature and power. The heat dissipation design ensures the stable operation of the equipment.

Application

It is widely applied in the plastic processing industry and is compatible with equipment such as injection molding machines, extruders, film blowing machines, bag blowing machines, wire drawing machines, granulators and plastic recycling machines. It can precisely heat the barrel, flange, die head, screw and other parts, improve the production quality of films, plates, profiles and other products, shorten the preheating time and reduce the scrap rate. Meanwhile, the surface temperature of the equipment is low, which can effectively improve the workshop environment and has a remarkable energy-saving effect.

By Laier Heating TO KNOW MORE ABOUT Laier Heating, PLEASE CONTACT US!

- kangpu@yckp.com

-

No.118, Xinyuan Road, Economic Development Zone, Yancheng, Jiangsu

Our experts will solve them in no time.