Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

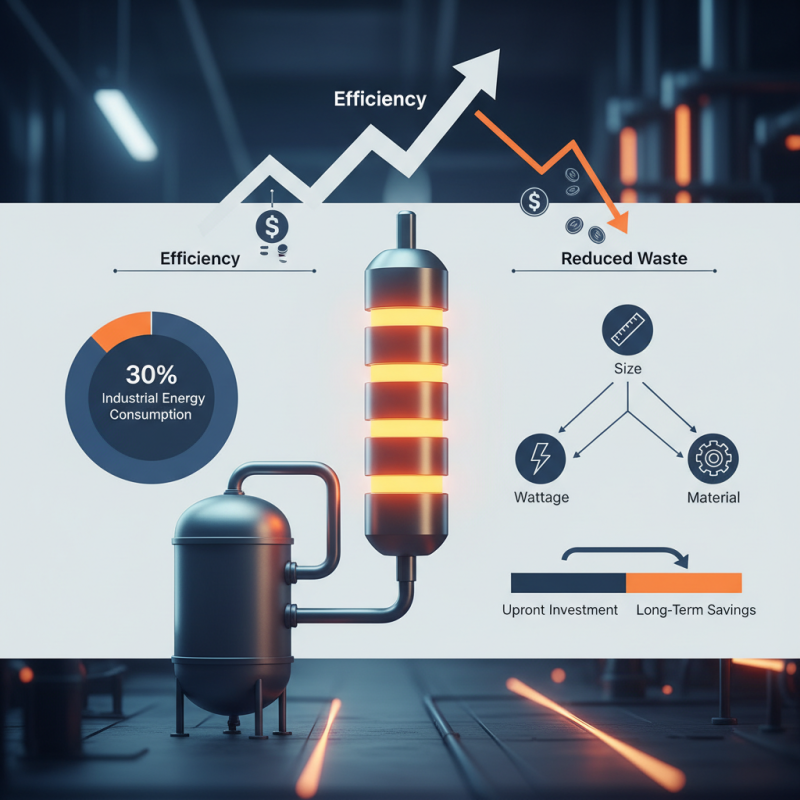

In various industries, efficient heating solutions are crucial. Rod heaters have emerged as vital components in processes requiring precise temperature control. According to the U.S. Department of Energy, industrial heating accounts for nearly 30% of energy consumption in manufacturing. This highlights the need for effective heating systems like rod heaters.

Rod heaters provide localized heating, essential for applications within tanks and pipelines. Their ability to maintain consistent temperatures reduces energy waste, making them cost-effective. For many companies, the choice of rod heaters significantly impacts operational efficiency. However, selecting the right type can be daunting. Factors such as size, wattage, and material must be considered carefully.

The market for heating elements is growing, yet many users underestimate potential energy savings. It’s crucial to recognize that not all rod heaters perform equally. As technology advances, newer models offer enhanced efficiency but may require a larger upfront investment. A thoughtful evaluation of options is necessary to ensure optimal performance and energy usage.

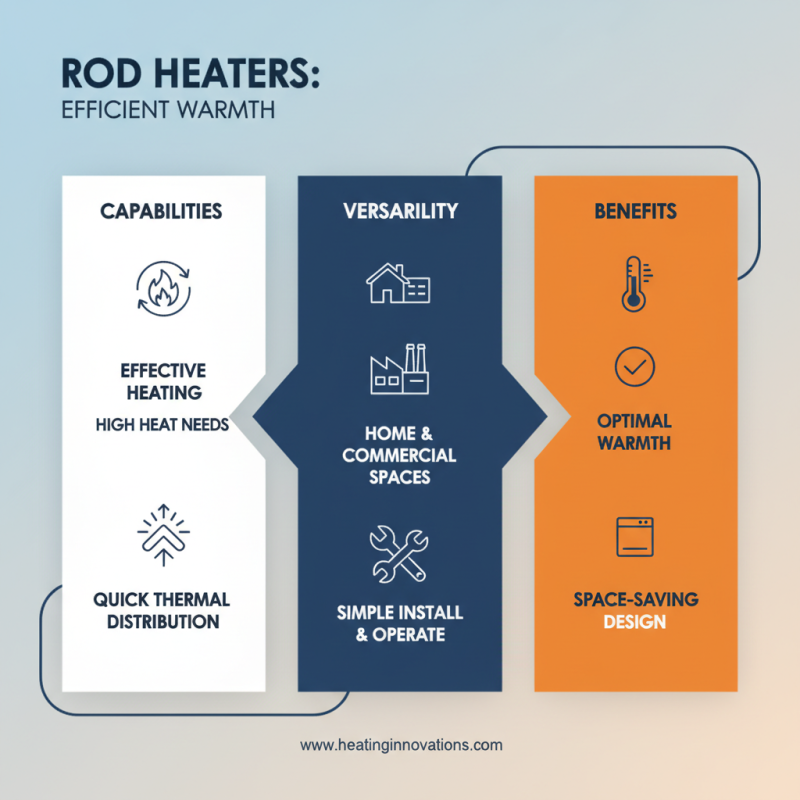

Rod heaters are popular for their effective heating capabilities. They are mostly used in areas where heating needs are high. Their design allows for quick and efficient thermal distribution. This feature makes them suitable for various environments, from homes to commercial spaces. Users often find rod heaters simple to install and operate. They save space while delivering optimal warmth where it's needed most.

Efficiency is a crucial factor when choosing a rod heater. Many promise quick heating, but results can vary. Some users experience delays in achieving desired temperatures. Factors like room size and insulation affect performance. It’s essential to choose a heater that fits your specific needs. Consider how often you use it and where it will be placed.

These heaters can be cost-effective in the long run. However, energy consumption can add up. Users should monitor usage to avoid surprises on electricity bills. Maintenance is also necessary to ensure peak efficiency. Regular cleaning and inspections can prevent issues. Sometimes, minor adjustments can make a significant difference in performance. Efficient heating is essential, but getting there can require some effort and reflection.

When selecting a rod heater, several key features should guide your decision. One crucial aspect is wattage. According to industry reports, heaters between 1000 to 3000 watts are ideal for most applications. Higher wattage means faster heating. However, it also translates to increased energy consumption. Balance is essential.

Another important consideration is the temperature range. Many models offer settings from 50°F to 150°F. This versatility allows users to optimize conditions for different needs, such as aquariums or greenhouse heating. Look for units with precise thermostats for better control over temperature stability.

Durability is also a significant factor. Costs can add up if you need to frequently replace a rod heater. Materials like stainless steel or high-grade plastic enhance longevity. Yet, some cheaper options can perform well but may pose reliability issues. Assess the trade-offs. A more affordable heater might save money initially but could lead to frustration down the line. Always weigh your options carefully when choosing the right rod heater for your environment.

This chart compares the efficiency ratings of five different rod heaters based on their heating effectiveness and energy consumption.

Rod heaters are essential tools for both home and industrial applications. They efficiently heat fluids, maintain temperatures, and enable processes in various settings. According to industry reports, over 30% of heating solutions in industrial settings utilize rod heaters due to their efficiency.

In homes, these heaters play a significant role too. They can enhance comfort and energy efficiency. A study showed that homes using rod heaters could save up to 25% on heating costs. This makes them an attractive choice for homeowners looking to optimize energy use. However, they require proper installation and maintenance. Neglecting these aspects can lead to performance issues and increased costs.

For industrial use, the benefits are even more pronounced. Data indicates that proper temperature control in manufacturing can increase production quality by 15%. Yet, not all facilities utilize rod heaters effectively. Some overlook the need for routine maintenance, leading to potential inefficiencies. Inadequate installation may cause uneven heating, resulting in waste. These are critical aspects that require attention to fully leverage the advantages of rod heaters.

When comparing energy consumption in rod heaters, efficiency is key. Some models consume less electricity while providing the same heat output. Not all heaters are created equal. Differences in wattage can lead to distinct heating costs over time.

It's interesting to note that design impacts energy use significantly. A more streamlined design can enhance heat distribution. However, some users may overlook this factor. They might choose based on cost alone, missing potential savings on energy bills. For instance, a heater with higher efficiency ratings might cost more upfront but save money in the long run.

Heat-up time also plays a role. Some rod heaters take longer to reach desired temperatures, leading to higher energy consumption. Users often forget to consider how this affects overall efficiency. A quick heat-up feature can be beneficial, though sometimes it's undervalued. Thinking critically about these aspects can help make a more informed choice.

Rod heaters are essential for efficient heating in various applications. To ensure these units last and operate effectively, proper maintenance is crucial. Regularly inspecting heaters helps identify potential issues early. Look for signs of wear or damage on cords and connections. Noticing small problems can prevent costly repairs down the line.

Cleaning is another vital aspect. Dust and dirt can accumulate, affecting performance. Wipe down the heaters periodically using a soft cloth. Make sure to turn them off and unplug them before cleaning. Sometimes, we forget to clean, and then we face reduced efficiency.

Moreover, check the environment surrounding your rod heater. Ensure there's adequate airflow to prevent overheating. Lack of ventilation can lead to failures. Remember to keep flammable materials away. It might seem obvious, but neglecting these details can lead to serious issues. Maintaining a routine will make a significant difference in longevity.