Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of thermoplastic processing, maximizing efficiency is paramount for manufacturers seeking competitive advantages. Cast Nozzle Heaters are at the forefront of this revolution, offering significant improvements in thermal management and production reliability. Research indicates that companies implementing advanced heating technologies can achieve energy savings of up to 30%, alongside a substantial reduction in cycle times, which can enhance productivity by as much as 40% (Seamless Production Reports, 2022). These heaters not only optimize temperature control but also facilitate uniform heat distribution, effectively minimizing material degradation and waste. As industries worldwide continue to push for sustainable and cost-effective manufacturing solutions, the adoption of Cast Nozzle Heaters stands out as a crucial step toward operational excellence in thermoplastic processing.

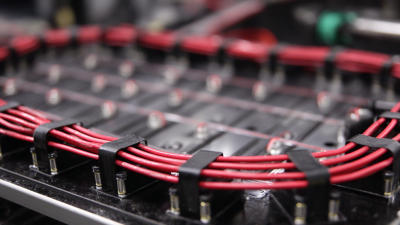

Cast nozzle heaters play a pivotal role in enhancing the efficiency of thermoplastic processing, particularly in the manufacturing of advanced composite materials. Recent advancements in processing techniques have highlighted the potential of utilizing long-fiber reinforced unidirectional thermoplastic composites, such as those reinforced with jute yarns. These materials demand precise thermal management during processing, and cast nozzle heaters provide this by maintaining optimal temperatures, resulting in smoother flow and improved material properties.

In addition, the integration of innovative materials like amphiphilic cellulose nanocrystals and polyglycerol-modified polyvinyl alcohol demonstrates the trend towards using sustainable and high-performance components in thermoplastic applications. The effectiveness of cast nozzle heaters becomes even more pronounced in these scenarios, as they enable better dispersion of additives and consistent processing conditions, which are vital for achieving high-quality final products. With ongoing developments in thermoplastic processing technologies, the importance of cast nozzle heaters in facilitating efficient and sustainable manufacturing processes cannot be overstated.

The adoption of cast nozzle heaters in thermoplastic processing brings forth significant advantages that are transforming manufacturing efficiency. One of the key benefits includes enhanced thermal management, which facilitates more consistent and uniform heating. Research indicates that effective thermal control can lead to a reduction in energy consumption by approximately 20%, which is critical in an industry that constantly seeks to minimize operational costs. Furthermore, better temperature regulation helps improve product quality by reducing the occurrence of defects during processing.

Another noteworthy advantage of cast nozzle heaters is their impact on production speed. By achieving rapid temperature recovery, manufacturers can streamline their operational workflows, thus reducing cycle times. Recent industry data shows that manufacturers implementing advanced heating solutions, such as these heaters, have reported up to a 30% increase in output efficiency. This enhancement allows for greater flexibility in production schedules and the ability to accommodate high-volume orders without compromising quality. As companies strive to innovate and improve their manufacturing processes, cast nozzle heaters emerge as a pivotal technology in optimizing thermoplastic processing.

| Key Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Consistent Temperature Control | Ensures uniform heating across the nozzle for optimal material flow. | Reduces defects and increases product quality. |

| Energy Efficiency | Lower energy consumption compared to traditional heating methods. | Decreases operational costs. |

| Rapid Heat-Up Time | Fast heating capabilities minimize downtime for production. | Increases throughput and production efficiency. |

| Reduced Maintenance | Durable design means less frequent replacements and repairs. | Lowers maintenance costs and enhances reliability. |

| Improved Material Properties | Maintains ideal temperatures to preserve the integrity of the plastic. | Results in better mechanical properties of the finished product. |

In the realm of thermoplastic processing, the efficiency of heating methods significantly impacts production speed and energy consumption. Traditional heating methods, such as band heaters and cartridge heaters, often lead to uneven temperature distribution and longer warm-up times. These methods typically require manual adjustments to maintain optimal temperatures, which can cause frequent fluctuations during production. The inconsistent heating results in defects in the final product and increases downtime, ultimately affecting the bottom line.

In contrast, cast nozzle heaters offer a groundbreaking solution by providing uniform heat distribution directly to the injection nozzle. Their design ensures rapid heat-up times and precise temperature control, minimizing the risk of overheating or underheating the thermoplastic material. Additionally, cast nozzle heaters are integrated efficiently with modern machinery, allowing for seamless operation and reduced energy consumption. This enables manufacturers to achieve higher throughput rates while maintaining exceptional product quality, illustrating how cast nozzle heaters can revolutionize thermoplastic processing compared to traditional heating methods.

Real-world applications of cast nozzle heaters are transforming the thermoplastic processing industry. By providing uniform heating and minimizing energy loss, these advanced heating systems improve productivity and efficiency. According to a recent industry report by MarketsandMarkets, the global market for thermoplastic processed goods is expected to reach $600 billion by 2027, with innovations in heating technology playing a crucial role in this growth. One notable success story involves a leading automotive parts manufacturer that integrated cast nozzle heaters into their production line. This upgrade resulted in a 30% reduction in energy consumption and significantly increased their production speed, demonstrating the tangible benefits of this technology.

Real-world applications of cast nozzle heaters are transforming the thermoplastic processing industry. By providing uniform heating and minimizing energy loss, these advanced heating systems improve productivity and efficiency. According to a recent industry report by MarketsandMarkets, the global market for thermoplastic processed goods is expected to reach $600 billion by 2027, with innovations in heating technology playing a crucial role in this growth. One notable success story involves a leading automotive parts manufacturer that integrated cast nozzle heaters into their production line. This upgrade resulted in a 30% reduction in energy consumption and significantly increased their production speed, demonstrating the tangible benefits of this technology.

When considering the adoption of cast nozzle heaters, it's important to focus on specific application needs. Tip: Evaluate the temperature consistency required for your processes; even minor fluctuations can impact product quality. Additionally, adopting a phased implementation can help in assessing performance gains without a full-scale commitment. Another key advantage is the heaters' compatibility with various thermoplastics, which can lead to greater material versatility in manufacturing processes. Tip: Conduct thorough testing with your specific materials to ensure optimal performance and reliability. These real-world implementations highlight how cast nozzle heaters are not just innovative, but essential for maintaining a competitive edge in thermoplastic processing.

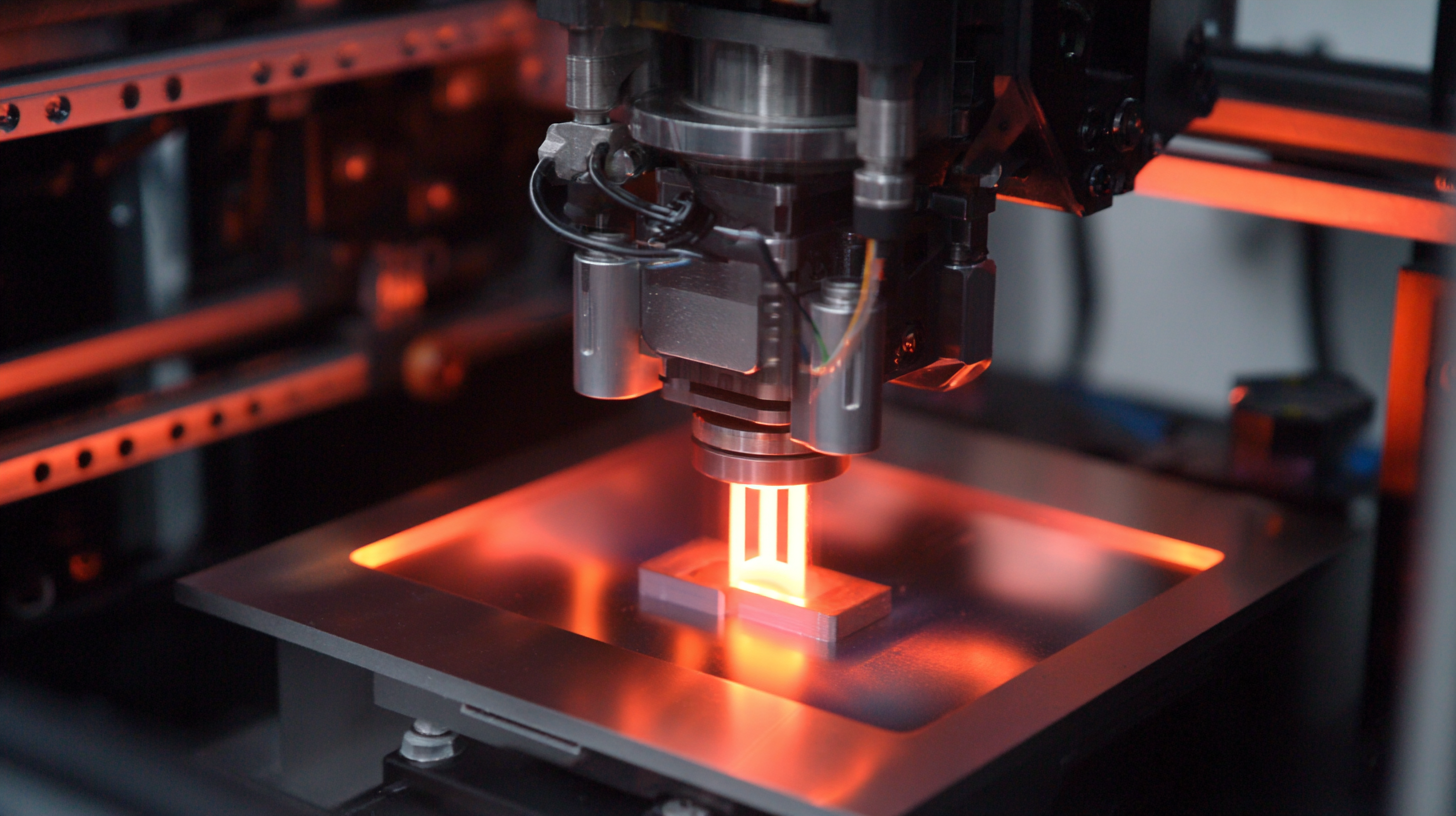

At the forefront of thermoplastic processing innovation, cast nozzle heaters are reconfiguring how manufacturers approach efficiency in their operations. As highlighted during the recent AICE 2025 SMM Aluminum Industry Conference, advancements in cast nozzle heating technology are paramount in driving down energy consumption while maintaining the integrity of thermoplastics. The integration of smart heating elements allows for precise temperature control, significantly reducing response times and minimizing waste during production.

Tips for implementation include regular maintenance of heating elements to ensure optimal performance and utilizing advanced monitoring systems to track temperature fluctuations in real-time. Furthermore, investing in training for staff on the latest technological advancements can enhance operational understanding, resulting in smoother workflow and increased output.

Future trends indicate a focus on developing more sustainable heating solutions that not only improve efficiency but also align with environmental standards. The transition towards smarter, energy-efficient manufacturing processes is essential, as industries aim to reduce their carbon footprint while meeting growing demand for high-quality thermoplastic products. Embracing these innovations in cast nozzle heating is crucial for companies striving to stay competitive in a rapidly evolving market.