Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of industrial heating solutions, the Heater Bar stands out as a versatile and efficient component utilized across various applications. These devices are essential for maintaining optimal temperatures in environments ranging from manufacturing to food processing. As industry expert Dr. Emily Carter articulates, "The Heater Bar not only enhances operational efficiency but also contributes to temperature consistency in critical processes." This statement underscores the importance of Heater Bars in industries where precision and reliability are paramount.

Heater Bars function by converting electrical energy into thermal energy, making them an integral part of many heating systems. Available in multiple configurations and sizes, they can be tailored to suit specific requirements, providing targeted heating solutions for different materials and processes. This adaptability makes Heater Bars indispensable in applications such as plastics manufacturing, aerospace systems, and even in laboratory settings where controlled heating is vital.

Understanding the operational mechanisms and applications of Heater Bars is crucial for professionals seeking to optimize their processes. As technology advances, the role of Heater Bars continues to evolve, promising improved performance and efficiency in thermal management. This article delves into the functionality, benefits, and various applications of Heater Bars, shedding light on their importance in contemporary industry practices.

A heater bar is a specialized device designed to provide consistent heating across various surfaces and materials. Typically made from high-quality metal, these bars are equipped with heating elements that generate warmth when an electric current passes through them. This process allows the heater bar to reach desired temperatures quickly and evenly, making it an efficient tool for multiple applications.

In industrial contexts, heater bars are frequently utilized in processes such as plastic molding, where they help maintain the necessary temperatures to keep materials malleable. In addition, they are employed in packaging applications, ensuring that seals and joints are properly fused by applying heat directly to the surfaces that need bonding. By understanding how heater bars function and their diverse applications, industries can leverage their benefits to enhance productivity and maintain quality standards in manufacturing processes.

Heater bars, also known as heating elements, play a crucial role in various industries by providing precise thermal energy required for multiple applications. The fundamental working principle of heater bars revolves around the conversion of electrical energy into heat through resistive heating. When an electric current is passed through the material, resistance generates heat, efficiently maintaining the necessary temperature across diverse environments. For instance, in the plastics industry, heater bars are employed in extrusion processes to keep materials at optimal processing temperatures, ensuring quality and consistency in manufactured products.

In the food processing sector, heater bars aid in maintaining sanitary temperatures for food products, preserving the integrity of flavor and nutrition. According to the Global Food Processing Equipment Market report, the demand for temperature control solutions in food industries is projected to grow significantly, driven by the increasing necessity for automation and efficiency. In addition, temperature management in the pharmaceutical industry, where precision is paramount, relies heavily on these heating elements to ensure the stability of sensitive compounds during production.

Furthermore, heater bars are extensively utilized in the renewable energy sector, specifically in solar heating systems. They assist in complementing solar thermal energy by maintaining efficiency during lower sunlight conditions. As noted in the Renewable Energy Market Analysis report, the integration of such thermal technologies can enhance energy conservation efforts and improve output efficiency, positioning heater bars as vital components in the transition towards sustainable energy solutions.

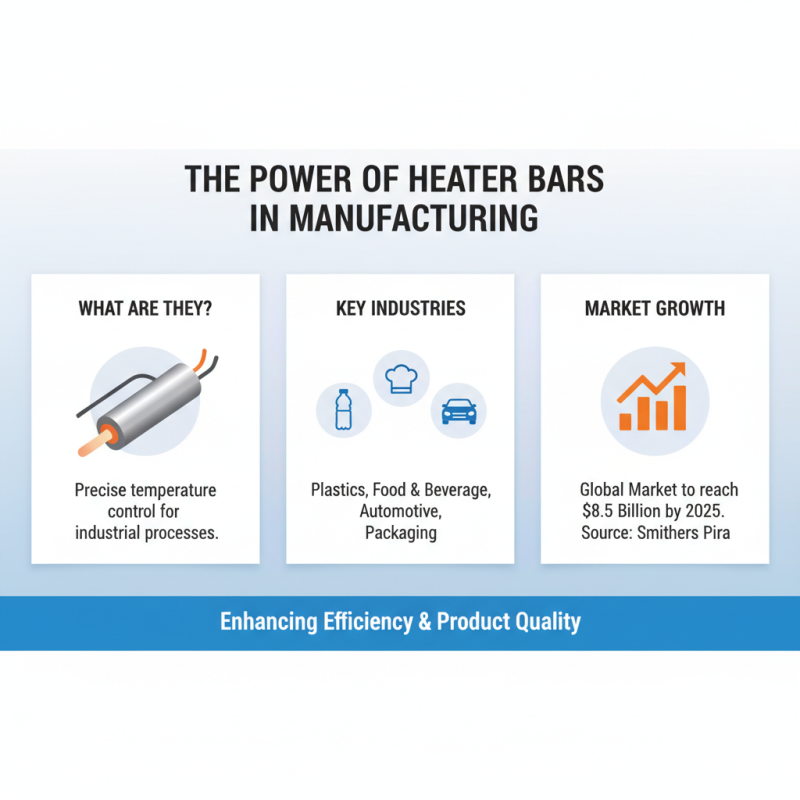

Heater bars play a crucial role in a variety of manufacturing processes, offering precise temperature control necessary for effective production. In industries such as plastics, food, and automotive, heater bars are utilized to ensure consistent heating of materials. According to a market research report by Smithers Pira, the global market for industrial heating elements, including heater bars, is expected to reach $8.5 billion by 2025, indicative of their growing importance in operational efficiency and product quality.

In the plastics industry, heater bars are predominantly used in processes like extrusion and molding. They provide the necessary heat to melt plastic resins, ensuring a uniform flow and consistent product characteristics. The effective use of heater bars can lead to a reduction in energy consumption by up to 25%, as highlighted in a report by the International Energy Agency (IEA), making them not only vital for quality control but also for improving the sustainability of manufacturing practices. The precise heating capability of these devices helps in reducing cycle times and enhances overall production efficiency.

Similarly, in the food processing sector, heater bars are employed for applications such as pasteurization and drying, where maintaining specific temperatures is critical for food safety and quality. A study published in the Journal of Food Science noted that improper heating can lead to spoilage and health risks, emphasizing the importance of consistent heat application. By integrating advanced heater bar technology, manufacturers can improve product longevity and consumer safety, further highlighting the versatility and importance of heater bars across various manufacturing applications.

Heater bars are essential components in various thermal applications, functioning by converting electrical energy into heat through resistance. Their design typically involves a metal alloy encased in an insulating material, which allows for efficient heat distribution. When comparing heater bars to other heating elements, several factors come into play, including efficiency, response time, and application suitability. According to a report by the International Energy Agency, electric heating systems, such as heater bars, are favored for their fast response times and precise temperature control, making them ideal for industries that require quick and reliable heating solutions.

In contrast, traditional heating elements like radiant heaters or convection systems offer different advantages. For instance, radiant heaters provide immediate warmth to objects in their line of sight, which can be beneficial for specific applications like space heaters or outdoor heating. However, their efficiency tends to decrease in larger or drafty spaces. A comparative study from the Electric Power Research Institute indicates that while heater bars can achieve an energy efficiency of up to 90% in controlled environments, other heating elements may only reach around 70% to 80% under similar conditions. This efficiency difference is crucial in sectors such as manufacturing, where heat loss can significantly impact overall operational costs.

Ultimately, while heater bars excel in high-efficiency applications, the choice of heating element largely depends on the specific thermal installation requirements. Industries must consider factors like space constraints, required temperature ranges, and the physical properties of the materials being heated to determine the optimal heating solution for their needs.

Heater bars are essential devices in various industries, used to provide efficient heating solutions for materials or processes. However, as technology advances, the challenges within the heater bar sector have become more pronounced. Issues such as thermal inefficiency and the risk of material degradation due to excessive heat present significant hurdles. According to a recent market report by Research and Markets, the global heater bar market is expected to grow at a CAGR of approximately 5% over the next five years, emphasizing the need for innovative solutions to overcome these challenges.

In response to these issues, manufacturers are exploring advanced materials and designs that enhance performance and longevity. Innovations such as the use of ceramic insulators and high-performance coatings can significantly improve thermal efficiency and reduce energy consumption. Additionally, smart technology integration, including IoT sensors, allows for real-time monitoring and control, leading to decreased energy usage and optimal heating performance. This level of technological integration can help ease operational challenges and meet the evolving demands of various applications in automotive, packaging, and food processing industries.

Tips: When selecting heater bars for specific applications, consider factors such as material compatibility, temperature requirements, and energy efficiency ratings. Proper maintenance, including regular inspections and monitoring of operational parameters, can further extend the lifespan of heater bars and ensure optimal performance.