Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

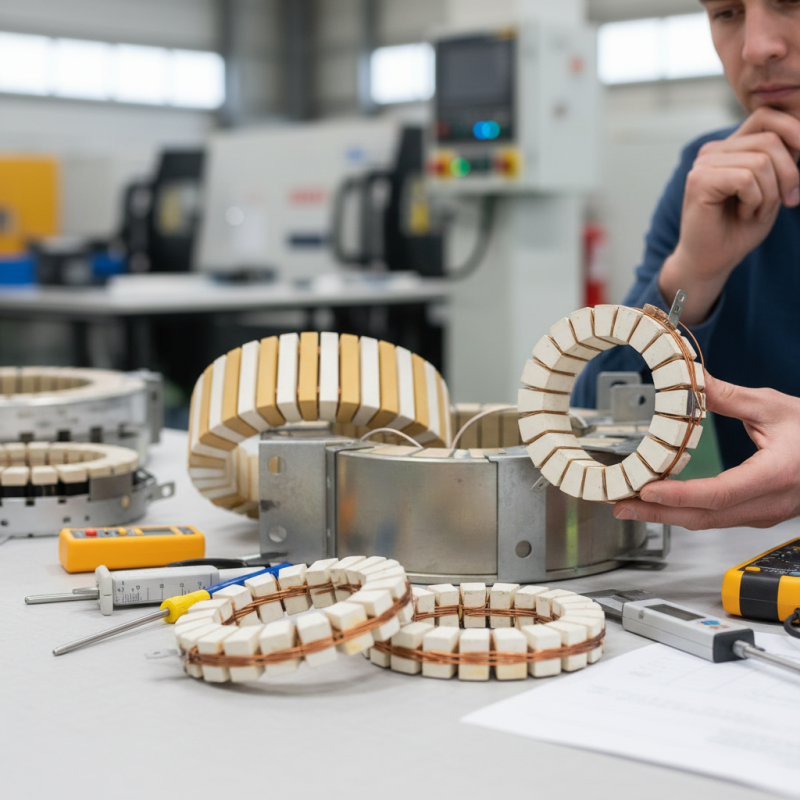

When it comes to selecting the right Ceramic Band Heater, understanding specific needs is essential. Expert engineer Sarah Johnson once stated, “Choosing the right heater is critical for efficiency and performance.” This advice rings true for manufacturers and technicians alike.

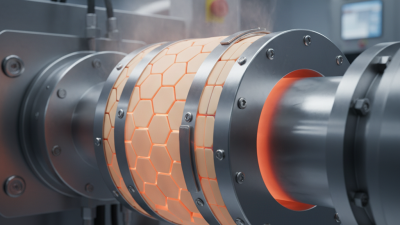

Ceramic Band Heaters are crucial in various industries. They provide consistent heat to different components. Their effectiveness can greatly impact production processes. Many factors influence the right choice: size, watt density, and temperature range. Each detail matters when ensuring optimal performance.

Finding the ideal Ceramic Band Heater can be challenging. Misjudgments can lead to excessive energy use or insufficient heating. Reflecting on past choices can guide better decisions. Taking the time to assess needs carefully is vital for achieving success. Every heater must align with specific operational requirements.

Ceramic band heaters play a crucial role in various industrial applications. They are known for their efficiency and durability. These heaters provide consistent heat, ensuring that processes run smoothly. Industries often rely on precise temperature control for optimal operation. Ceramic band heaters fit this requirement perfectly.

Many users underestimate the importance of choosing the right heater. It's not just about the wattage or size. Material and construction matter significantly. A well-made ceramic band heater can improve energy efficiency. It also minimizes maintenance costs. However, not all heaters are created equal. Some may exhibit uneven heat distribution, causing issues in production.

It’s essential to consider specific needs when selecting a heater. What are the dimensions of your equipment? How much heat does your process require? Reflecting on these details can lead to better outcomes. Making informed choices promotes safety and efficiency in the workplace. In some cases, companies may choose a heater based on price alone. This approach can lead to dissatisfaction later on.

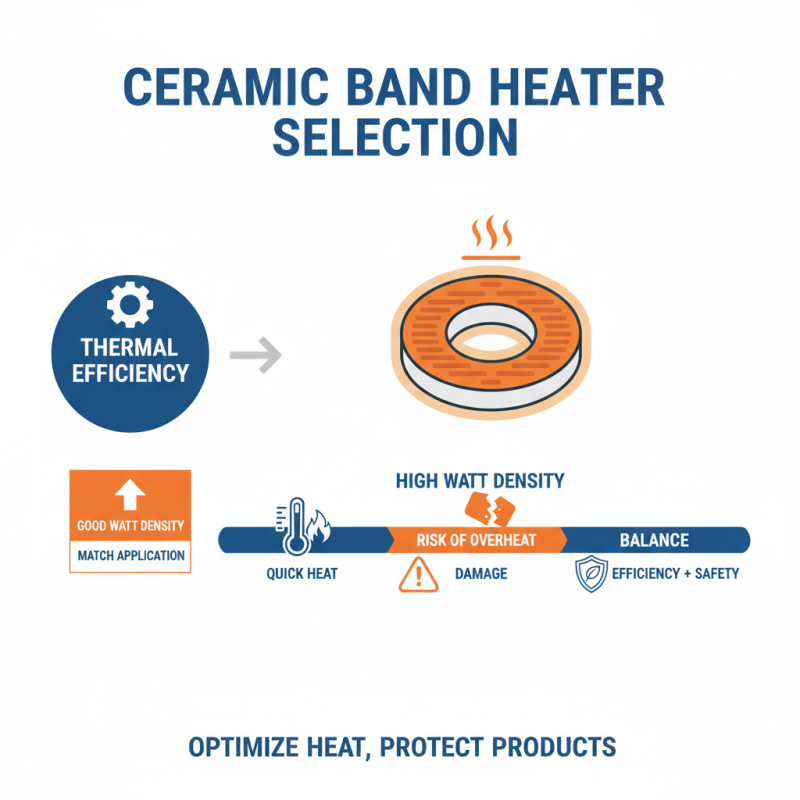

When selecting a ceramic band heater, consider its power rating. The watt density affects heating efficiency. A heater that’s too powerful can cause overheating. Balance is crucial for optimal performance.

Tip: Assess your application. If you're heating delicate materials, choose a lower watt density. This prevents damage and maintains quality.

Next, look at the size and fitting. A proper fit ensures even heat distribution. Measure the diameter and width of your components carefully. An incorrect size can lead to hot spots or inefficiency.

Tip: Use shims or insulation for a better fit if needed. This practice is not always perfect, but it can enhance heating uniformity.

Lastly, evaluate the temperature range. Different applications require different heat levels. Ensure the heater can handle your specific needs. Check for maximum and minimum temperature ratings.

Tip: Always think about future applications. It’s better to choose a versatile heater than to replace it down the line. Remember, flexibility can save you trouble later.

When selecting a ceramic band heater, evaluating thermal efficiency is crucial. Look for a good watt density. It should match your heating application. High watt density can heat up quickly. However, it may lead to overheating. Too much heat can damage heated items. Ensure you balance efficiency with safety.

Performance ratings also matter. Check the heater’s ability to maintain temperature. Does it fluctuate widely? Consistent temperatures are key for processes. Consider the heating times, too. Some heaters reach desired temperatures faster than others. This speed can impact your operational efficiency.

Thermal insulation quality plays a role, too. Good insulation minimizes energy loss. This not only saves on costs but also improves overall performance. Be wary, though. Lower quality insulation may increase heat loss. This can lead to higher energy consumption. In the long run, investing in efficient products pays off. Assess your specific needs carefully before making a choice.

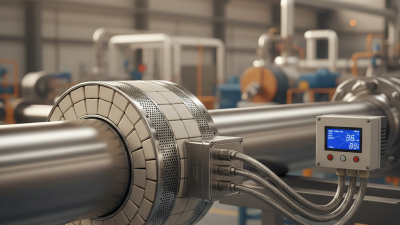

Choosing the right ceramic band heater requires careful attention to size, power, and voltage.

The size of the heater must fit your specific application. Measure the diameter and length of the component it will heat. If the band is too tight or too loose, it may not heat evenly. This can lead to hot spots or inefficient heating, which can affect performance.

Power is another critical factor. The wattage needs to match your heating requirements. If you choose a heater with insufficient power, it will struggle to maintain the desired temperature. Conversely, a heater with excessive power may cause overheating. Understanding the required power output can prevent these issues.

Voltage is equally important. Make sure the voltage rating of the heater matches your power supply. An incorrect voltage can damage the heater or lead to failure. It's vital to check your setup before making a purchase. Customizing your choice can lead to better performance, but it's not always easy. You may find the specifications confusing at times.

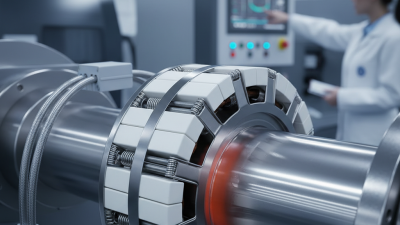

When selecting a ceramic band heater, comparing manufacturers is essential. Different companies have various industry standards for quality. Some may prioritize efficiency, while others emphasize safety. Researching these differences helps in making informed decisions.

One critical aspect to consider is the manufacturer’s testing processes. Some companies may not have stringent quality control. This can lead to inconsistent performance in their heaters. It's wise to examine user reviews and feedback. Sometimes, a lesser-known brand may offer better durability. Finding a balance between cost and reliability is challenging.

In addition to performance, look into the materials used. Manufacturers often vary in the type of ceramic and insulation they use. This can affect heating efficiency and lifespan. Consider the application environment too. Heaters in high-vibration settings may need extra reinforcement. Taking the time to reflect on these details will pay off in the long run.

| Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|

| Max Temperature: 800°C | Max Temperature: 750°C | Max Temperature: 850°C |

| Power Range: 100-1200W | Power Range: 200-1500W | Power Range: 300-2000W |

| Material: High-grade Aluminum | Material: Stainless Steel | Material: High-Temp Inconel |

| Warranty: 1 Year | Warranty: 2 Years | Warranty: 1.5 Years |

| Applications: Plastics, Ceramics | Applications: Food Processing, Chemicals | Applications: Aerospace, Automotive |

| Energy Efficiency: High | Energy Efficiency: Moderate | Energy Efficiency: Very High |