Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Cast Nozzle Heater is crucial for ensuring optimal performance in temperature-sensitive applications. As industries increasingly demand precision and efficiency in their manufacturing processes, the selection of appropriate heating elements becomes paramount. Cast Nozzle Heaters play a vital role in delivering consistent heat to materials, preventing defects, and maintaining production quality.

In this guide, we will explore key considerations for selecting the ideal Cast Nozzle Heater tailored to your specific requirements. Factors such as compatibility with various materials, heating efficiency, and temperature control are essential in narrowing down the options available. By understanding these elements, you can make informed decisions that enhance productivity and reduce operational costs in your applications. Whether you are involved in plastic processing, food production, or any other industry requiring precise thermal management, the right choice of a Cast Nozzle Heater can significantly impact your overall results.

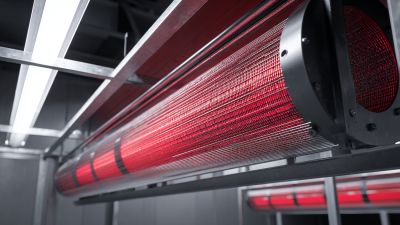

Cast nozzle heaters play a crucial role in maintaining optimal temperature control during the injection molding process. These heaters are specifically designed to heat the molten plastic as it moves from the barrel to the mold, ensuring that the material achieves the desired viscosity and flow properties. Understanding the functionality of these heaters is essential for selecting the right type for your application, as they can significantly influence both the quality of the final product and the efficiency of the manufacturing process.

When choosing a cast nozzle heater, it's important to consider factors such as the heater's watt density, temperature range, and compatibility with the nozzle material. A higher watt density can provide quicker heating, while the temperature range should match the specific requirements of the materials being processed. Additionally, ensuring compatibility with the nozzle material will prevent damage and prolong the lifespan of the heating element.

**Tips:**

1. Always evaluate the thermal conductivity of the nozzle you are using to determine the best watt density for efficient heating without causing hot spots.

2. Consult technical specifications for temperature control to ensure the heater can manage the peak temperatures needed for your specific application.

By paying attention to these aspects, you can optimize your injection molding process, resulting in improved productivity and product quality.

This bar chart illustrates the comparison of temperature ranges and heating efficiency of various cast nozzle heaters. The data indicates ideal operating temperatures and power ratings which are crucial in selecting the appropriate heater for specific applications.

When selecting the right cast nozzle heater for your applications, it is crucial to start by identifying specific application requirements. These requirements can vary significantly based on the material being processed, temperature control needs, and the production environment. According to industry reports, nearly 60% of misapplications in heating systems stem from a failure to accurately define these requirements upfront. Understanding parameters such as thermal conductivity, required heating time, and the operational temperature range for the materials involved are foundational to choosing an appropriate heater.

Additionally, the manufacturing process can influence the ideal specifications for your cast nozzle heater. For instance, applications involving high-viscosity materials typically require heaters that can maintain consistent temperatures without fluctuations. Data from a recent study found that temperature stability can enhance product quality by reducing defects by up to 25%. This serves as a reminder that investing time in recognizing your application’s specific needs—such as managing thermal expansion in molds or ensuring uniform heating—can lead to improved efficiency and reduced downtime in production lines.

Prioritizing these factors will not only streamline the selection process but also optimize overall system performance.

When selecting the right cast nozzle heater, evaluating material compatibility and

thermal conductivity is crucial. Different materials can significantly affect the performance and longevity of a heater.

For instance, heaters made from high-grade stainless steel can maintain structural integrity up to 800°F,

while others may fail at lower temperatures due to corrosion or thermal stress.

According to engineering reports, materials that exhibit high thermal conductivity, such as aluminum and copper,

can enhance heat transfer efficiency. This can lead to improved energy savings of up to 30%

compared to less conductive materials.

Tips for selecting the right materials include performing a detailed analysis of the substances that

will contact the heater. It is advisable to consult compatibility charts for various alloys and plastics to ensure they can withstand the specific operating temperatures

and chemical exposures they will face. Additionally, evaluating the thermal conductivity of

the heater material can result in a more efficient heating process, which is particularly important in precision applications

where maintaining consistent temperatures is vital.

Another important consideration is the heater's insulation properties. Insulation affects not only the efficiency of thermal transfer

but also energy consumption. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends using

materials with low thermal conductivity for insulation to minimize heat loss, thus optimizing performance. Always factor in these elements

in conjunction with both the operating environment and the specific requirements of your application for optimal results.

When selecting a cast nozzle heater for your applications, understanding the appropriate power rating and heating capacity is crucial for optimal performance. The power rating, usually measured in watts, determines how quickly the heater can raise the temperature of the surrounding materials. It is essential to align this rating with your operational needs; for instance, if you are working with materials that require rapid heating or have high thermal mass, a higher power rating will be beneficial. Conversely, if your application involves delicate materials that may be sensitive to temperature changes, a lower power rating can allow for more controlled heating.

Another key factor is the heating capacity, which refers to the amount of heat a heater can deliver over a set period. This capacity should match the required temperature and throughput for your specific process. Understanding the thermal characteristics of the materials you are working with will help you calculate the necessary heating capacity. For efficient operation, consider the thermal conductivity and specific heat of the materials to ensure that they are adequately heated without excessive energy usage. Additionally, factors such as the environmental conditions where the heater will operate should also be assessed to guarantee reliable and consistent performance.

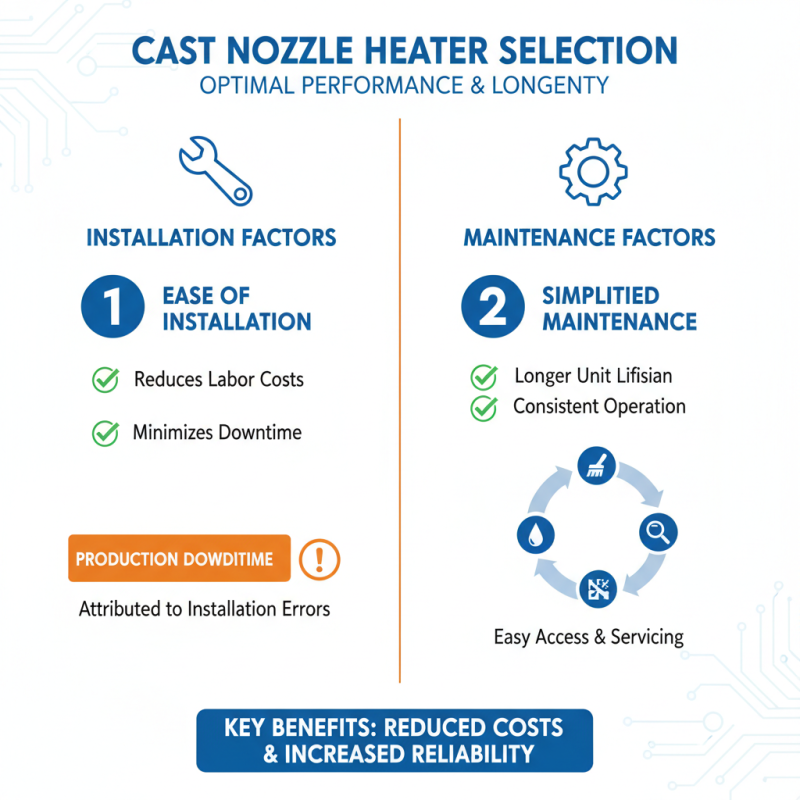

When selecting a cast nozzle heater, installation and maintenance factors play a pivotal role in ensuring optimal performance and longevity of the unit. The ease of installation should be a primary consideration, as complex setups can lead to increased labor costs and extended downtime. According to industry reports, approximately 30% of downtime in production can be attributed to installation errors or complicated procedures. A well-designed heater that allows straightforward installation not only reduces initial costs but also minimizes operational disruptions.

Maintenance is another critical aspect that should not be overlooked. Regular upkeep is essential for maintaining performance efficiency, and heaters that require less frequent maintenance can significantly reduce operational costs. Data from the Heating Elements Manufacturers Association (HEMA) suggest that regular maintenance can enhance the operational life of cast nozzle heaters by up to 50%. Ease of access for maintenance tasks is crucial; designs that allow for quick inspections and component replacements can lead to increased productivity. Therefore, evaluating the maintenance demands of a selected heater can help ensure that it aligns with the operational goals of your facility. Investing in a heater that simplifies both installation and ongoing maintenance can result in substantial long-term savings and efficiency improvements.