Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

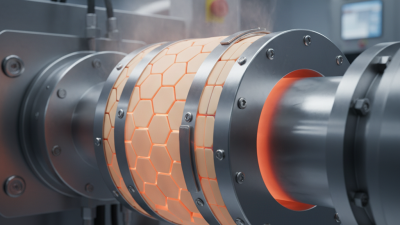

When it comes to industrial heating solutions, the choice of equipment greatly impacts performance. A Ceramic Insulated Band Heater stands out as a popular option. It is designed for efficient heating while using less energy. These heaters often feature advanced insulation, minimizing heat loss and maximizing efficiency.

Many industries rely on precision heating for various applications. Their construction allows for rapid temperature control, making them ideal for tasks that require consistency. The durable ceramic material also provides longevity, reducing the need for frequent replacements. However, not all applications may benefit from this type of heater. Assessing specific demands is crucial to ensure a perfect match.

Investing in a Ceramic Insulated Band Heater might raise questions. Is it worth the cost? Does it truly improve efficiency? These reflections are essential. While the heater promises advanced benefits, understanding your unique needs ultimately guides the best choice.

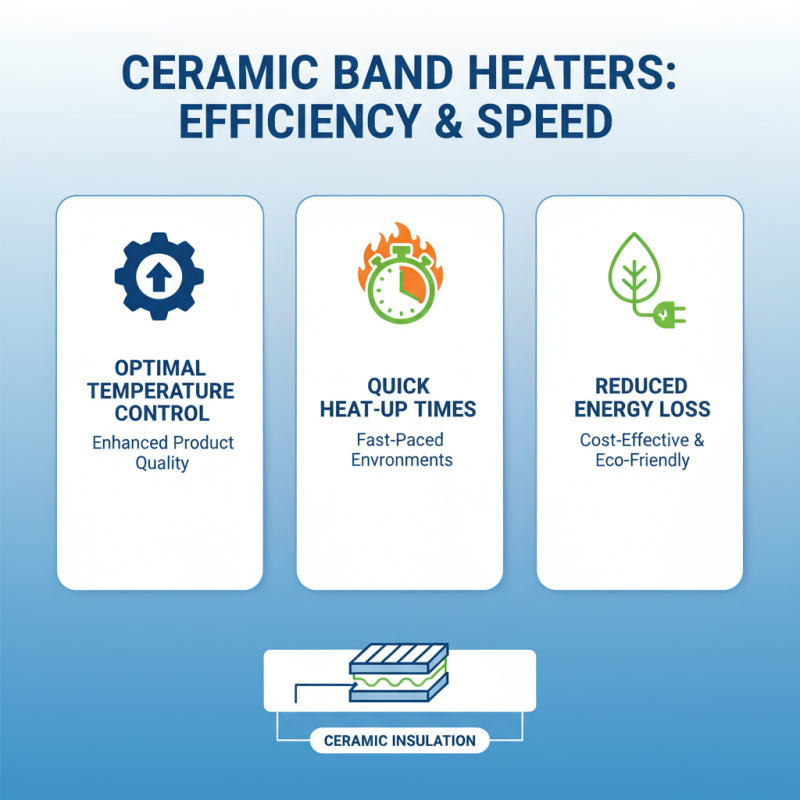

Ceramic insulated band heaters stand out in various applications due to their unique advantages. Unlike traditional heaters, these ceramic models provide efficient heating with reduced energy loss. Their design allows for quicker heat-up times, essential in fast-paced environments. A good illustration is in manufacturing processes where optimal temperature control can enhance product quality.

Another significant benefit is durability. Ceramic insulation protects against wear and tear, extending the heater’s lifespan. In contrast, other heater types may struggle under high temperatures. This means fewer replacements and maintenance tasks, which can be a hassle. The upfront investment can seem daunting. However, considering long-term savings is vital.

Lastly, the ability to provide uniform heat distribution is crucial. This feature prevents hotspots, aiding in consistent results. However, selecting the right size and configuration is essential. Improper choices may lead to inefficiencies. Users must carefully evaluate their specific needs to make informed decisions. In this way, ceramic insulated band heaters offer both reliability and performance for those willing to invest time in their selection.

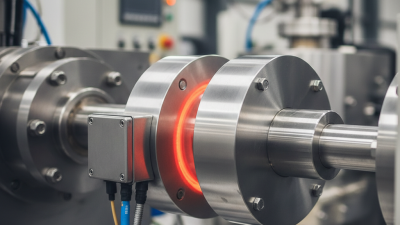

Ceramic insulation is a game changer in the heating industry. It significantly boosts energy efficiency. According to recent studies, ceramic insulated band heaters can improve energy savings by up to 30%. This is partly due to their ability to retain heat better than traditional options. Less heat loss means lower energy bills and a more eco-friendly operation.

Performance is another key benefit. Ceramic insulation distributes heat uniformly. This reduces hot spots, which can lead to material degradation. Reported data show that materials treated with ceramic heaters have a longer lifespan. However, some users report challenges with installation. Proper alignment is crucial for optimal performance. Misalignment can negate some of the insulation benefits.

Moreover, while ceramic insulation materials are generally reliable, their cost can be a concern. The initial investment is higher. Yet, many find that the long-term energy savings justify the upfront price. Evaluating the total cost of ownership is vital. It's important to make informed choices that balance upfront costs with ongoing savings and performance gains.

| Feature | Ceramic Insulated Band Heater | Traditional Band Heater |

|---|---|---|

| Energy Efficiency | High - Up to 20% savings | Moderate - Standard effectiveness |

| Temperature Uniformity | Excellent | Good |

| Weight | Lightweight | Heavier |

| Durability | High | Moderate |

| Installation | Simple | More Complex |

| Applications | Versatile (various materials) | Limited (specific applications) |

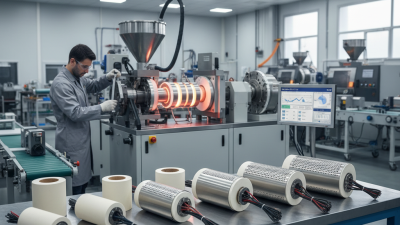

Ceramic band heaters are widely used across various industries due to their efficiency and adaptability. In the plastics industry, they are crucial for providing uniform heat to extruders and injection molding equipment. According to a recent report by the Plastics Industry Association, about 70% of manufacturing facilities now utilize ceramic heaters to ensure consistent product quality.

The food processing sector has also embraced ceramic band heaters. They are used for keeping food products at optimal temperatures during production. A study from FoodTech Insights highlights that temperature control in food processing can reduce spoilage rates by 15%. This not only preserves quality but also improves safety standards.

Tips: When selecting heaters, consider the specific application. Assessing the required temperature range is vital. Be mindful of the environment too. High humidity or exposure to certain chemicals may affect performance.

Additionally, in a production setting, it’s essential to monitor heater performance regularly. If not, efficiency may decrease unnoticed. Mismanagement could lead to increased energy costs and potential downtime. Regular checks can mitigate these issues and enhance productivity.

When selecting a ceramic insulated band heater, several factors should be considered. One crucial element is the heater's temperature range. Different applications require varying heat levels. Ensure the heater can achieve the necessary temperature for your specific needs. It’s also important to evaluate the material compatibility. Using a heater that works well with your setup can boost efficiency.

Another aspect to consider is the size and shape. Band heaters come in various dimensions, suitable for different machinery. You might find one that perfectly fits your equipment or one that requires modifications. It’s easy to overlook these details in a hurry, yet they play a significant role in performance.

Lastly, energy efficiency is worth pondering. A more efficient heater may lower energy costs over time. However, this often requires an upfront investment. Balancing the initial cost with long-term savings can be tricky. Reflecting on these considerations can lead to a better choice, even if it feels overwhelming at first.

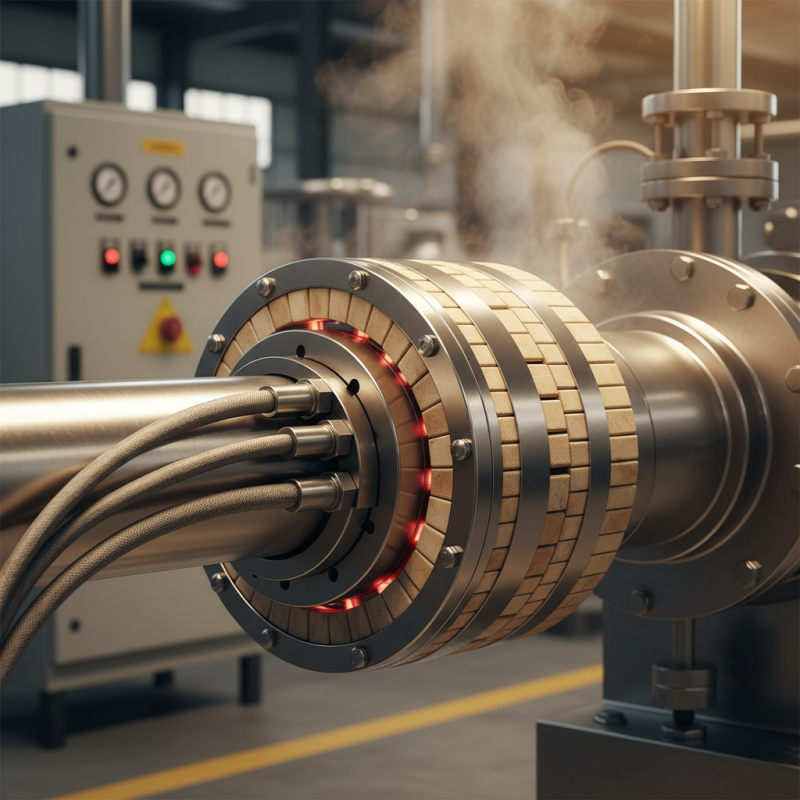

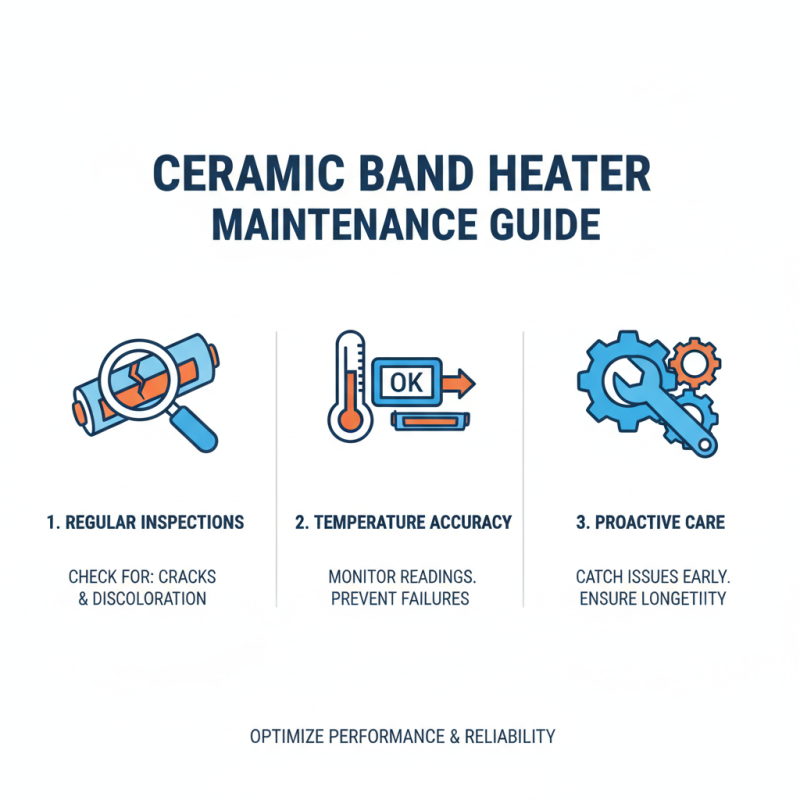

Ceramic band heaters are popular for many industrial applications. To ensure their longevity, proper maintenance is essential. Regular inspections can help you catch small issues before they escalate. It's crucial to check for signs of wear, such as cracks or discoloration. Monitoring temperature accuracy is also vital; false readings can lead to equipment failure.

One tip is to clean the ceramic insulation frequently. Dust and grime can build up and affect performance. Use a soft cloth to wipe the exterior carefully. Avoid abrasive cleaners; they can cause damage. Additionally, ensure proper installation to prevent mechanical stress. Misalignment can lead to uneven heating and premature wear.

Another important aspect is to manage thermal cycling. Rapid temperature changes can impact the heater’s lifespan. Gradually increase or decrease the temperature during operations. This approach can minimize thermal shock. Lastly, keep an eye on the connections. Loose connections may cause electrical fluctuations. Addressing these issues promptly will help maintain efficiency and safety.