Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In today's industrial landscape, the demand for energy efficiency and effective heating solutions is paramount. Ceramic Insulated Band Heaters have emerged as a pivotal technology, significantly enhancing operational efficiency and reducing energy costs in various applications. According to a report by the U.S. Department of Energy, implementing advanced insulation materials in heating systems can yield energy savings of up to 30%. These heaters not only provide uniform heat distribution but also minimize heat loss, leading to improved process control and product quality.

Furthermore, a study by the Global Market Insights reveals that the market for industrial heaters, including Ceramic Insulated Band Heaters, is expected to reach $10 billion by 2026, driven by increasing industrial automation and stringent energy regulations. By incorporating Ceramic Insulated Band Heaters, industries can unlock a new level of efficiency, driving both production and sustainability forward.

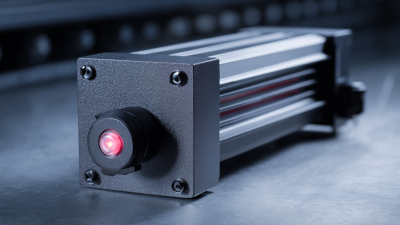

Ceramic insulated band heaters are pivotal in industrial applications, primarily due to their design and functionality. These heaters feature a unique ceramic insulation that allows for higher temperature capabilities while minimizing heat loss. This innovative insulation reduces energy costs and increases efficiency in heating processes, making them ideal for various manufacturing sectors. The robust construction ensures that these heaters can endure hostile environments, contributing to their longevity and reliability in production lines.

Ceramic insulated band heaters are pivotal in industrial applications, primarily due to their design and functionality. These heaters feature a unique ceramic insulation that allows for higher temperature capabilities while minimizing heat loss. This innovative insulation reduces energy costs and increases efficiency in heating processes, making them ideal for various manufacturing sectors. The robust construction ensures that these heaters can endure hostile environments, contributing to their longevity and reliability in production lines.

Tips for Optimal Use:

To maximize the efficiency of ceramic insulated band heaters, ensure proper installation. A snug fit around the workpiece is essential for effective heat transfer, reducing dead spots. Regular maintenance checks are also advisable to prevent wear and tear, ultimately prolonging the heater's lifespan. Additionally, consider integrating temperature controls for precise heating, which can prevent overheating and allow for more consistent results.

With their ability to maintain high temperatures and improve energy efficiency, ceramic insulated band heaters are becoming a cornerstone in enhancing production workflows. Understanding their design enables industries to leverage their full potential, thus driving improved operational outcomes.

Ceramic insulated band heaters are increasingly becoming crucial in various industrial applications due to their unique advantages. These heaters utilize ceramic insulation, which significantly enhances energy efficiency. By minimizing heat loss during operation, manufacturers can achieve optimal temperature control while reducing energy consumption. This is particularly vital in the context of industrial electrification, which aims to transition machinery from traditional non-electric sources to electric-powered systems, thereby driving down energy costs and supporting sustainability goals.

In conjunction with advancements in technology, such as Artificial Intelligence and Industry 4.0, the integration of ceramic insulated band heaters can further streamline manufacturing processes. The ability to maintain consistent temperatures improves product quality and reduces cycle times, which aligns with the industry's push towards digital transformation. As manufacturers increasingly focus on high-quality development, the incorporation of these heaters not only fulfills operational requirements but also positions them favorably within the competitive landscape of smart manufacturing.

Ceramic insulated band heaters are becoming increasingly popular in industrial settings due to their unique ability to optimize performance while delivering significant cost efficiency and energy savings. These heaters are designed with advanced ceramic insulation that minimizes heat loss, allowing for a more focused and efficient heating process. By directing heat where it is needed most, industries can reduce their energy consumption, which not only lowers operational costs but also promotes a more sustainable approach to manufacturing.

Furthermore, the durability and longevity of ceramic band heaters contribute to enhanced cost-effectiveness over time. Traditional heating solutions may require frequent replacements or maintenance, leading to increased labor and material costs. In contrast, ceramic band heaters are built to withstand extreme conditions and prolonged use, resulting in fewer disruptions and a smoother production workflow. This resilience ensures that companies can maintain high levels of efficiency while enjoying reduced downtime, thus maximizing output and profitability in industrial applications.

Ceramic insulated band heaters are increasingly being utilized across various industrial sectors due to their efficiency and versatility. In the plastics industry, for example, these heaters provide precise temperature control, which is crucial for processes such as extrusion and injection molding. The ceramic insulation allows for minimal heat loss, ensuring that the targeted materials are heated uniformly, which ultimately enhances product quality and reduces cycle times.

In the food and beverage sector, ceramic insulated band heaters play a vital role in maintaining optimal temperatures during food processing and packaging. Their ability to withstand high temperatures while providing consistent heat makes them ideal for applications such as melting fats or maintaining temperatures in holding tanks. Additionally, they are used in pharmaceutical manufacturing, where stringent temperature controls are necessary. The durability and reliability of ceramic heaters help in meeting the rigorous manufacturing standards required in this highly regulated industry.

The adoption of ceramic insulated band heaters across these sectors not only improves operational efficiency but also contributes to energy savings, making them a smart choice for industries looking to enhance productivity while minimizing operational costs.

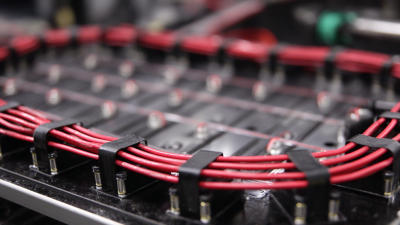

When integrating ceramic insulated band heaters into industrial applications, proper installation and maintenance are essential to maximize their efficiency and longevity. First, it is crucial to ensure that the band heater fits tightly and uniformly around the application. Misalignment can lead to uneven heating and energy loss. During installation, operators should also pay attention to the electrical connections, ensuring they are secure and protected from potential damage, which is critical to maintaining the integrity of the system under various operational conditions.

When integrating ceramic insulated band heaters into industrial applications, proper installation and maintenance are essential to maximize their efficiency and longevity. First, it is crucial to ensure that the band heater fits tightly and uniformly around the application. Misalignment can lead to uneven heating and energy loss. During installation, operators should also pay attention to the electrical connections, ensuring they are secure and protected from potential damage, which is critical to maintaining the integrity of the system under various operational conditions.

Regular maintenance practices can significantly extend the lifespan and effectiveness of these heaters. Inspecting for wear and tear, ensuring that insulation remains intact, and checking for signs of overheating are essential steps. Implementing infrared thermography can provide valuable insights into the operational efficiency of the heating elements, allowing for proactive maintenance before problems escalate. By adhering to these best practices, industries can not only enhance the performance of ceramic insulated band heaters but also contribute to more sustainable energy management and operational reliability.