Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the quest for efficient heating solutions, the merits of the Ceramic Insulated Band Heater have become increasingly evident. Leading industry expert Dr. John H. Miller, a renowned thermal management specialist, once stated, “The integration of ceramic insulation in band heaters fundamentally transforms energy efficiency and performance.” This assertion highlights the advantages of utilizing Ceramic Insulated Band Heaters over traditional options, particularly in industrial and manufacturing settings where precision and efficiency are paramount.

As businesses strive to optimize their heating processes, the Ceramic Insulated Band Heater stands out for its remarkable ability to minimize heat loss while maximizing thermal output. This innovative technology not only ensures a consistent temperature but also reduces energy consumption, leading to significant cost savings in the long run. With rising energy costs and environmental concerns pressing industries to adopt greener practices, the adoption of Ceramic Insulated Band Heaters is a forward-thinking choice that aligns with modern sustainability goals.

In this discussion, we will explore the unparalleled benefits of Ceramic Insulated Band Heaters, including their design efficiency, energy savings, and applications across various industries. By understanding the advantages offered by this cutting-edge technology, businesses can position themselves at the forefront of heating solutions while contributing to a more sustainable future.

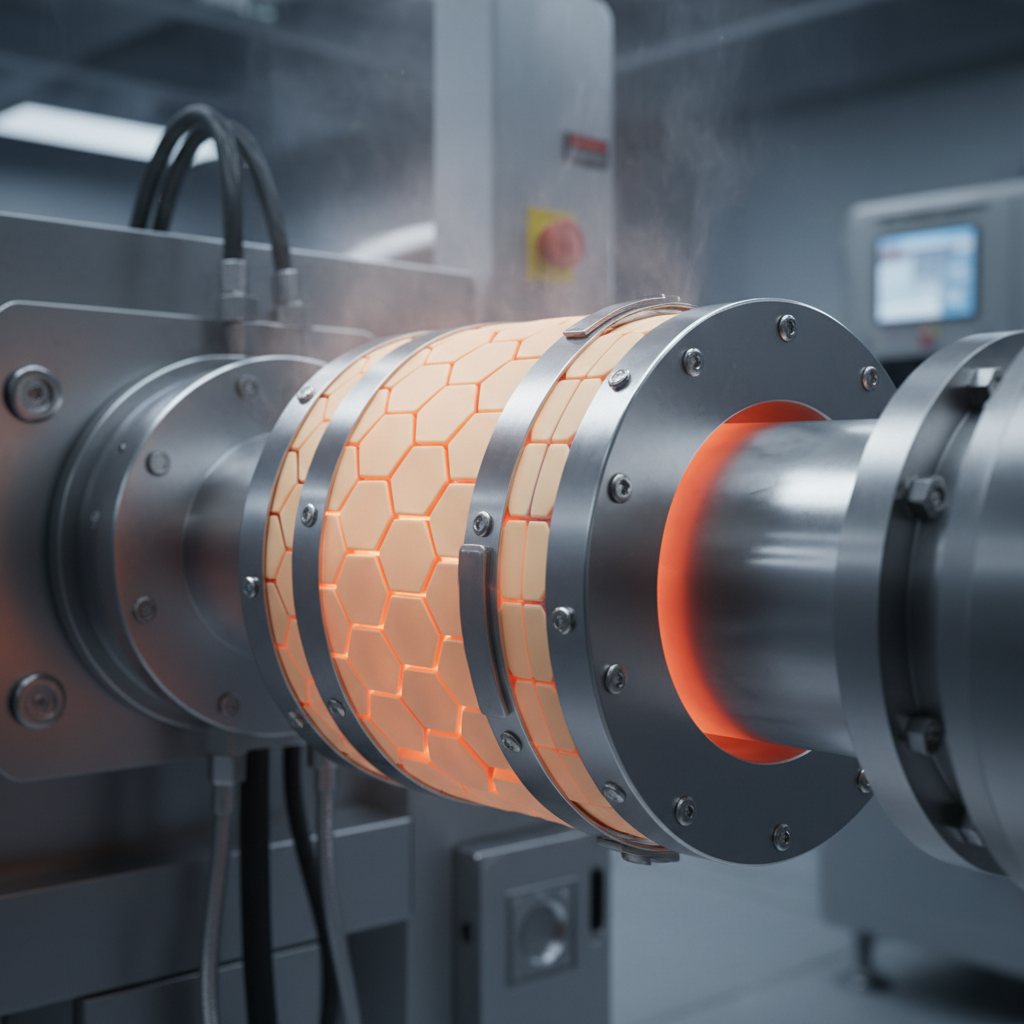

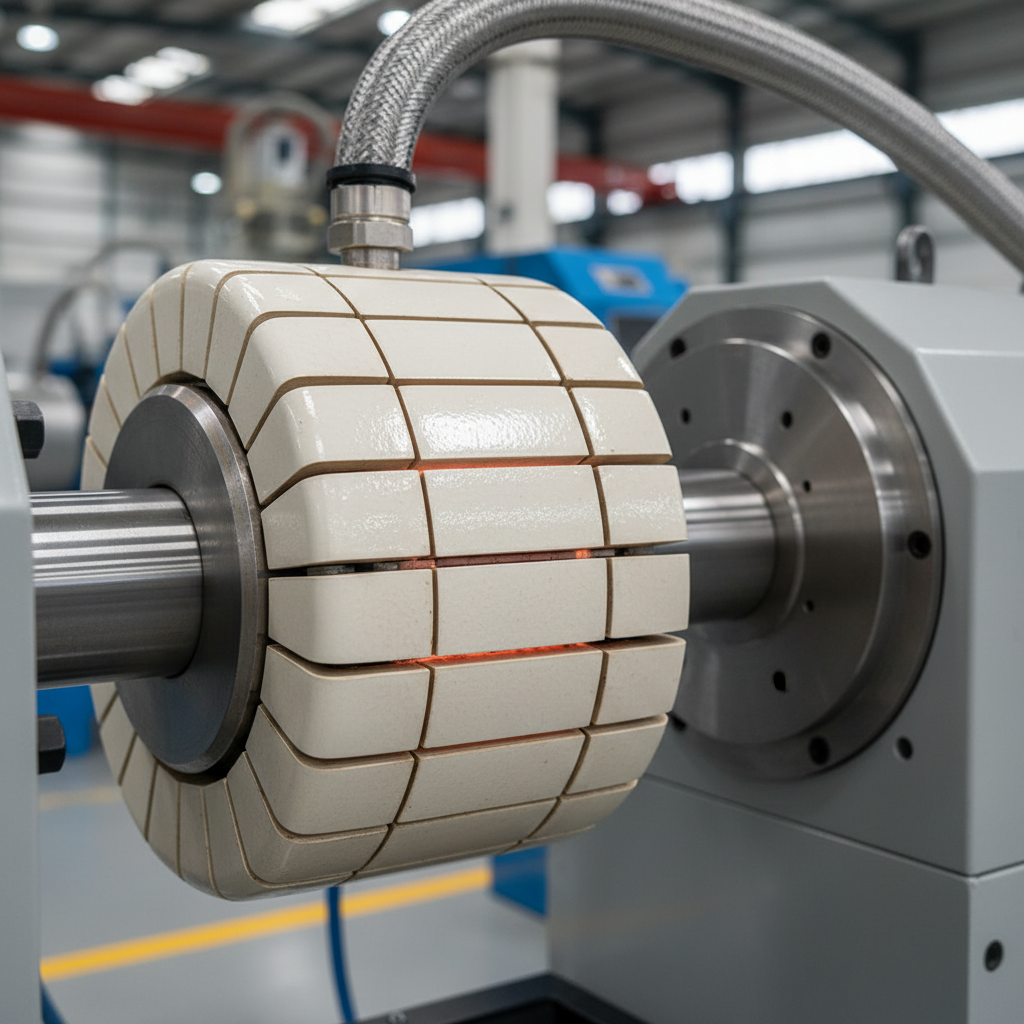

Ceramic insulated band heaters are an excellent choice for industrial heating applications due to their unique design features that enhance efficiency and performance. These heaters typically consist of a ceramic insulation layer that encases a heating element, which allows for superior heat retention and minimal energy loss. The ceramic insulation not only provides excellent thermal stability but also protects the heating element from damage, prolonging the life of the heater. This design ensures that heat is uniformly distributed across the heated surface, providing consistent temperatures for various materials.

Another notable design feature of ceramic insulated band heaters is their ability to withstand high operating temperatures. Unlike traditional metal heaters, ceramic materials can endure extreme conditions without deforming or degrading, making them ideal for processes that require high heat, such as plastic molding or chemical processing. Additionally, their lightweight construction makes them easier to install and handle, reducing setup times and labor costs. The combination of durability, efficiency, and high-performance capabilities makes ceramic insulated band heaters a top choice for businesses looking to optimize their heating processes.

Ceramic insulated band heaters are gaining popularity due to their superior energy efficiency compared to traditional heating options.

One of the primary benefits of using these heaters is their ability to retain heat more effectively. The ceramic insulation prevents heat loss, allowing the heater to operate at lower energy inputs while achieving optimal temperatures.

This not only leads to reduced energy consumption but also results in lower operational costs for businesses and manufacturers.

Furthermore, the durability of ceramic insulated band heaters contributes to their efficiency. Unlike other materials that may degrade or lose insulating properties over time, ceramic maintains its performance under high temperatures, ensuring that energy is used more effectively throughout the heater's lifespan.

This longevity, combined with lower energy requirements, makes ceramic insulated band heaters an environmentally friendly choice, minimizing the carbon footprint associated with heating processes.

In addition, their consistent performance reduces the need for frequent replacements, ultimately leading to a more sustainable operation.

Ceramic insulated band heaters play a crucial role in various industries, offering efficient heating solutions that enhance productivity. In the plastics industry, for instance, these heaters are commonly used to maintain the optimal temperature of barrels in extruders and injection molds. The uniform heat distribution ensures that the material is processed smoothly, minimizing defects and improving the quality of the final product.

In the food processing sector, ceramic insulated band heaters are also invaluable. They help to keep food products at a consistent temperature during cooking and processing, ensuring food safety and quality. Additionally, in chemical manufacturing, these heaters provide reliable heating for reactors and tanks, allowing for precise temperature control necessary for complex reactions. Their versatility and efficiency make ceramic insulated band heaters a preferred choice across a wide range of applications, driving consistency and performance in industrial processes.

When comparing ceramic insulated band heaters with other heating solutions, it’s essential to recognize the efficiency and performance metrics that set them apart. According to a report by the U.S. Department of Energy, industrial heaters can account for up to 30% of a facility’s energy consumption. Ceramic insulated band heaters can improve overall energy efficiency by offering up to 90% thermal efficiency due to their high resistance to heat loss. This efficiency results from the superior insulation properties of ceramic materials, which minimize heat waste and allow for faster heat-up times.

In contrast, traditional metal band heaters typically operate at a lower efficiency rate around 70-80%. A study by the Institute of Electrical and Electronics Engineers indicates that these heaters not only consume more energy but also have a shorter lifespan due to overheating and thermal cycling. By opting for ceramic insulated band heaters, industries can not only reduce operational costs by up to 25% but also enhance the longevity of their heating equipment, making them a preferred choice for applications requiring consistent and reliable heating solutions.

Ceramic insulated band heaters are a popular choice for efficient heating due to their ability to provide uniform temperature distribution and enhanced energy efficiency. To ensure the longevity of these heaters, regular maintenance is essential. One of the primary tips for care is to routinely inspect the heating element for any signs of wear or damage. Over time, ceramic materials may experience cracking or degradation, which can reduce performance. Regular checks allow for timely replacements and prevent more significant issues down the line.

Additionally, it's crucial to keep the heater clean and free from dust and debris. A buildup can impede heat transfer and lead to overheating, shortening the heater’s lifespan. Consider employing a gentle cleaning regimen, such as using a soft brush or cloth. Furthermore, maintaining proper installation, including secure fittings and proper electrical connections, contributes significantly to optimal performance. Addressing these maintenance aspects can ultimately save on energy bills while ensuring consistent heating efficiency, particularly as colder months approach and energy costs rise.

| Feature | Details |

|---|---|

| Heating Efficiency | Ceramic insulated band heaters provide superior heating efficiency, reducing energy consumption. |

| Heat Retention | The insulation minimizes heat loss, allowing for consistent temperature maintenance. |

| Durability | Ceramic heaters are built to last, with high resistance to thermal shock and wear. |

| Maintenance Tip: Regular Cleaning | Ensure the unit is free of dust and debris to maintain optimal performance. |

| Maintenance Tip: Temperature Monitoring | Regularly check temperature settings to avoid overheating and damage to the unit. |

| Maintenance Tip: Inspect Wiring | Periodically inspect electrical connections and wiring for signs of wear or damage. |

| Cost-Effectiveness | While the initial cost may be higher, the energy savings and longevity lead to reduced overall costs. |