Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As industries seek to enhance operational efficiency and reduce energy costs, the adoption of innovative heating solutions has become paramount. The Radiant Process Heater (RPH) emerges as a front-runner in this quest, offering significant advantages over conventional heating methods. According to a recent report by the U.S. Department of Energy, radiant heating processes can achieve energy efficiencies of up to 95%, significantly minimizing wastage and lowering carbon footprints. This technological advancement not only contributes to sustainability goals but also supports industries in maximizing productivity.

With the global industrial heating market expected to reach $50 billion by 2025, driven by factors such as stringent energy regulations and the growing need for process optimization, the integration of Radiant Process Heaters is more critical than ever. This exploration delves into the myriad benefits of RPHs, emphasizing their role in shaping the future of industrial heating solutions through efficiency and innovation.

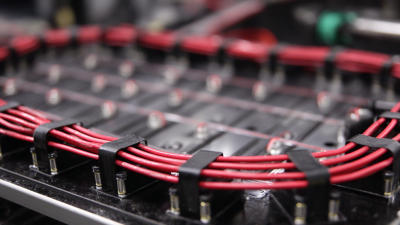

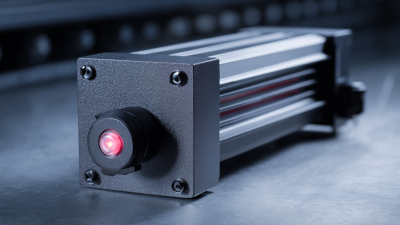

Radiant process heaters play a crucial role in modern industrial applications by offering efficient heat transfer and precise temperature control. These systems utilize infrared radiation to directly warm objects and surfaces, minimizing energy losses associated with traditional heating methods like convection. Key components of radiant heaters include heating elements, reflectors, and control systems, all designed to enhance performance. The ability to heat a targeted area rather than the surrounding air leads to significant energy savings and increased operational efficiency.

In addition to their efficiency, radiant heaters are adaptable and suitable for various industrial settings, from manufacturing to warehousing. The incorporation of innovative materials and technologies continues to advance their functionality. Recently, there have been efforts to reduce fuel consumption and CO2 emissions, focusing on optimizing combustion processes. These trends indicate a strong commitment within the industry to not only improve energy efficiency but also to address environmental concerns, making radiant process heaters a sustainable option for the future of industrial heating solutions.

Radiant heaters have emerged as an innovative solution in industrial heating, particularly regarding energy efficiency and operational cost reduction. By utilizing advanced technologies, radiant process heaters provide effective thermal management while minimizing energy consumption. This efficiency is critical in today's economic landscape, where reducing operational costs directly impacts profit margins for manufacturers and service providers alike.

Recent developments in high-efficiency heating systems highlight the potential for integrating various technologies to enhance energy performance. For example, the integration of phase change materials (PCM) with radiant heating systems has been shown to optimize thermal performance, designed specifically for modern energy demands. Analyzing such systems reveals their capacity to significantly lower energy expenses while maintaining or improving heating effectiveness. As industries increasingly prioritize sustainability and cost-effectiveness, the adoption of radiant heaters represents a pivotal shift toward more responsible energy use, making them an essential component of future industrial heating solutions.

This chart illustrates the operational cost savings achieved through the implementation of radiant process heaters across various industries, showcasing the energy efficiency benefits.

Radiant heating solutions have seen significant advancements in recent years, positioning them as a leading choice in industrial heating applications. According to a report by the U.S. Department of Energy, radiant heaters can achieve energy efficiencies of up to 90%, making them considerably more efficient compared to traditional convection heating systems. This efficiency not only reduces the energy consumption of industrial processes but also leads to lower operational costs, which is crucial for manufacturers aiming to enhance profitability while minimizing their carbon footprint.

Innovative technologies in radiant heating have paved the way for enhanced control and precision. For instance, the integration of smart sensors and IoT (Internet of Things) capabilities allows for real-time monitoring and adjustment of heating parameters. A recent industry analysis project estimates that the market for smart heating solutions is projected to grow at a CAGR of 15% over the next five years. As companies continue to invest in automation and smart technologies, radiant heating systems are becoming increasingly adaptable, capable of providing customized heating solutions that meet specific process requirements while optimizing energy use. These advancements highlight the role of radiant heating as a critical component in the evolution of industrial heating solutions.

Radiant process heaters have emerged as a transformative technology in various industrial applications, demonstrating exceptional efficiency and versatility. Industries such as manufacturing, food processing, and petrochemicals are increasingly leveraging these heaters due to their ability to transfer heat directly to materials, minimizing energy loss and ensuring precise temperature control. For instance, in the manufacturing sector, radiant heaters are used in metal fabrication and surface treatment processes, enhancing productivity by speeding up drying and curing times.

In the food processing industry, radiant heaters provide a stable and uniform heat source that is essential for applications such as roasting, drying, and baking. Their design allows for reduced emissions and improved safety, making them an attractive option for environmentally conscious businesses. Furthermore, in petrochemical operations, the ability to apply heat efficiently can lead to significant cost savings and improved product quality. The adaptability of radiant process heaters across such diverse industries highlights their pivotal role in driving innovation and efficiency in industrial heating solutions.

When considering industrial heating solutions, a comparative analysis of radiant heaters against traditional heating methods reveals significant advantages. Radiant process heaters operate by directly transferring heat to surfaces and objects, leading to enhanced energy efficiency. According to the U.S. Department of Energy, radiant heaters can achieve energy efficiencies of up to 95%, as they minimize heat loss through convection and maximize the effective use of energy. In contrast, traditional heating methods, such as convection heating systems, often struggle with efficiency rates around 60-70%, resulting in increased operational costs.

One notable advantage of radiant heaters is their ability to provide targeted heating, allowing for quicker processes and less energy waste. In industries such as manufacturing and food processing, where precise temperature control is crucial, radiant heaters can help reduce production times and improve product quality. A report from the International Energy Agency highlights that switching to radiant heating systems can yield a 30% reduction in energy consumption over the lifespan of the equipment.

**Tips:** When evaluating heater options, consider the total cost of ownership, which includes not just the initial investment but also maintenance and energy costs. Additionally, ensure that the heater is optimized for the specific application to achieve the best efficiency gains. Regularly assess the performance of heating systems to further enhance energy savings and operational effectiveness.

| Heating Method | Efficiency (%) | Heat Distribution (°C) | Energy Consumption (kWh) | Startup Time (min) | Maintenance Frequency (months) |

|---|---|---|---|---|---|

| Radiant Heater | 90 | 20-30 | 8 | 1 | 12 |

| Traditional Convection Heater | 70 | 30-40 | 12 | 5 | 6 |

| Infrared Heater | 85 | 15-25 | 10 | 2 | 8 |

| Steam Heater | 75 | 40-50 | 15 | 10 | 3 |