Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of efficient heating solutions, Industrial Infrared Heaters stand out as a groundbreaking technology that has transformed traditional heating methods. Renowned expert in thermal technologies, Dr. Emily Carter, emphasizes the significance of this innovation by stating, "Industrial Infrared Heaters not only provide superior energy efficiency but also enhance operational productivity across various industries." With their ability to deliver heat directly to objects and surfaces, these heaters minimize energy loss and reduce operational costs, making them an invaluable asset in industrial applications.

As industries continue to seek sustainable and cost-effective heating solutions, the benefits of Industrial Infrared Heaters become increasingly apparent. They offer precise temperature control, rapid heat-up times, and a reduction in harmful emissions, aligning with the global push towards greener practices. In this article, we will explore the top ten advantages of utilizing Industrial Infrared Heaters, highlighting how they contribute to efficiency, safety, and environmental responsibility while offering immense value to businesses across various sectors.

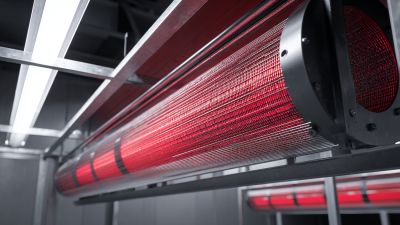

Industrial infrared heaters have revolutionized the heating solutions in various industries, primarily due to their ability to offer fast and efficient heating. Unlike conventional heating methods that warm the air before affecting surfaces, infrared heaters directly heat objects and people in their line of sight. According to a report by the International Energy Agency, infrared technology can achieve heating efficiency levels of up to 90%, significantly reducing energy consumption and costs. This direct heating method allows for rapid temperature changes, making it ideal for time-sensitive applications in manufacturing and processing.

One of the remarkable advantages of industrial infrared technology is its ability to provide instant heat. When an operator switches on an infrared heater, the heat is felt almost immediately, which can be crucial in settings where downtime must be minimized. A study conducted by the American Industrial Heating Association highlighted that processes using infrared heating can reduce cycle times by up to 30%. This leads to increased productivity, allowing businesses to meet tighter deadlines without sacrificing quality.

Tips for optimal use of infrared heaters:

Infrared heating systems have gained popularity in various industrial applications due to their remarkable energy efficiency and potential for cost savings. One of the key benefits of using these heaters is their ability to convert about 90% of the energy they consume into heat, compared to traditional heating methods that often lose significant energy through air movement and heat dissipation. According to a report by the U.S. Department of Energy, businesses can save up to 30% on heating costs by switching to infrared heating technology.

The direct heating mechanism of infrared heaters allows them to warm objects and surfaces rather than just the air, resulting in quicker temperature rises and maintaining warmth long after the system shuts off. This not only reduces energy use but also leads to a more comfortable environment for workers, enhancing productivity. For industries where heating demands vary, infrared heaters can also be a flexible option, enabling precise control over heat output and reducing operational costs.

**Tips:** When transitioning to an infrared heating system, consider implementing smart thermostats to further optimize energy usage. Regular maintenance is essential as well; keeping the heaters clean and free from obstructions can ensure maximum efficiency. Additionally, during initial installations, evaluate the layout carefully to position heaters at the most effective angles for uniform heat distribution.

This chart illustrates the top 10 benefits of using industrial infrared heaters, rated on a scale of 1 to 10. The ratings highlight their energy efficiency, cost savings, and additional advantages.

Industrial infrared heaters have emerged as a key technology in promoting energy efficiency and reducing environmental impact. One of the most significant advantages of these heaters is their ability to lower carbon footprints in various industrial applications. According to a report by the U.S. Department of Energy, infrared heating systems can achieve energy efficiencies of up to 90%, compared to traditional heating methods that often struggle to surpass 60%. This impressive efficiency translates directly into reduced energy consumption and, consequently, lower greenhouse gas emissions, making infrared heaters a smart choice for environmentally conscious companies.

Beyond energy efficiency, infrared heaters offer targeted heating capabilities that minimize heat loss. Unlike conventional systems that heat the air in a space, infrared heaters warm objects and surfaces directly. This targeted approach not only enhances heating performance but also reduces the overall energy demand. A study published in the International Journal of Energy Research highlights that shift from conventional heating to infrared technology can reduce emissions of CO2 by approximately 30% in specific manufacturing settings. By investing in infrared technology, industries can significantly contribute to climate change mitigation while optimizing their operational costs and energy usage.

| Benefit | Description | Environmental Impact | Energy Efficiency |

|---|---|---|---|

| 1. Quick Heating | Infrared heaters provide immediate heat transfer to objects. | Reduces time for heating spaces, thus saving energy. | High efficiency with minimal energy loss. |

| 2. Targeted Heating | Heats specific areas rather than the entire space. | Lower overall energy consumption, less CO2 emissions. | More efficient use of energy resources. |

| 3. Lower Operating Costs | Reduced energy bills due to efficient heating methods. | Contributes to lower carbon footprint through reduced energy use. | Lower fuel consumption translates to cost savings. |

| 4. Clean and Safe | No combustion gases produced, leading to cleaner air. | Reduction in air pollution compared to traditional heaters. | Use of electric energy promotes cleaner energy sources. |

| 5. Long Lifespan | Durable and less maintenance required over time. | Fewer replacements contribute to less waste and resources used. | Reduces the demand for new materials, enhancing sustainability. |

| 6. Adaptable Applications | Versatile for different industrial settings. | Flexibility can mean less overall energy expenditure. | Adaptation to energy needs leads to process efficiency. |

| 7. Improved Comfort | More consistent and uniform heat distribution in spaces. | Less reliance on auxiliary heating sources. | Enhances comfort without unnecessary energy use. |

| 8. Minimal Heat Loss | Direct heat transfer minimizes the loss of energy. | Less wasted energy contributes to reduced emissions. | Improves overall energy efficiency in operations. |

| 9. Environmentally Friendly | Utilizes renewable energy sources more effectively. | Supports cleaner production with lower emissions. | Promotes sustainability through smart energy use. |

| 10. Reduced Carbon Footprint | Lower greenhouse gas emissions compared to gas heating systems. | Contributes significantly to environmental goals. | Potential to utilize zero-emission energy sources. |

Industrial infrared heaters have gained popularity not just for their efficiency but also for their enhanced safety features. Unlike traditional heating methods that can pose risks of burns or fire hazards, infrared heaters operate at lower temperatures, significantly reducing safety concerns. The technology focuses on radiant heat transfer, which ensures that the surface temperature remains manageable. This aspect makes infrared heating suitable for environments where safety is paramount, such as in manufacturing plants, warehouses, and laboratories.

When implementing industrial infrared heating solutions, it’s essential to consider several safety tips. Ensure that heaters are installed at a safe distance from flammable materials and surfaces. Regular maintenance and inspections are crucial to keeping the equipment in optimal working condition. Additionally, utilizing infrared heaters with built-in safety mechanisms, such as automatic shut-off features, can further enhance workplace safety.

Moreover, operators should be trained on the specific safety features of the heaters they use. Understanding how to effectively monitor temperatures and recognizing potential hazards can make a significant difference in maintaining a safe working environment. By prioritizing safety alongside efficiency, businesses can enjoy the benefits of industrial infrared heaters while minimizing risk.

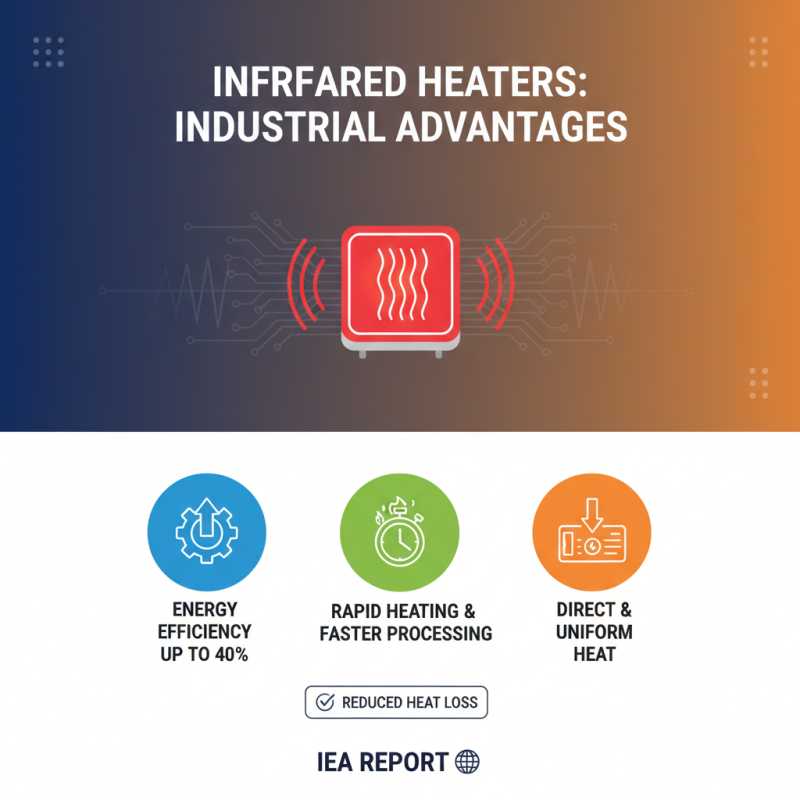

Infrared heaters have gained considerable traction in numerous industrial applications due to their efficiency and versatility. According to a recent report by the International Energy Agency (IEA), infrared heating technology can improve energy efficiency in industrial processes by up to 40% compared to traditional heating methods. This is particularly advantageous in environments where rapid heating is crucial, such as in manufacturing lines for coatings, plastics, and textiles. For instance, infrared heaters provide direct and uniform heat, minimizing heat loss and allowing for quicker processing times.

The adaptability of infrared heaters extends across various sectors including automotive, food processing, and glass production. In the automotive industry, infrared heating is often used for curing paints and finishes, facilitating faster application and drying times that enhance production efficiency. A study by the Department of Energy suggests that utilizing infrared technology in drying applications can cut energy consumption by as much as 30%. Similarly, in food processing, infrared heaters ensure even heating, which is essential for achieving consistent product quality while reducing overall cooking time. This capability positions infrared heaters as a critical asset for industries seeking to streamline operations and reduce energy costs while maintaining high standards of output.