Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

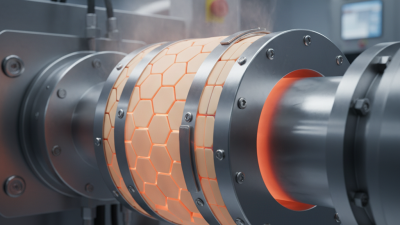

In the world of industrial heating solutions, the Ceramic Insulated Band Heater stands out as a top choice. Known for its efficiency and durability, it offers innovative features that improve performance. "Ceramic Insulated Band Heaters are game-changers in temperature control," says Jack Thompson, a leading expert in thermal technologies. This statement captures the essence of this essential equipment.

Today’s market demands reliable tools that can adapt to various tasks. The Ceramic Insulated Band Heater excels in these conditions. Its design allows for quick heating times and energy savings. Additionally, the ceramic insulation ensures reduced heat loss, which is critical in many applications. However, selecting the right model can be overwhelming. There are many options available, and not all meet the same standards of quality.

What should you consider when choosing a Ceramic Insulated Band Heater? Look for features that enhance performance, like precise temperature regulation and easy installation. It’s essential to balance these benefits with the potential drawbacks. Some users report that finding the ideal size can be tricky. This guide will delve into the standout features and benefits, helping you make informed decisions.

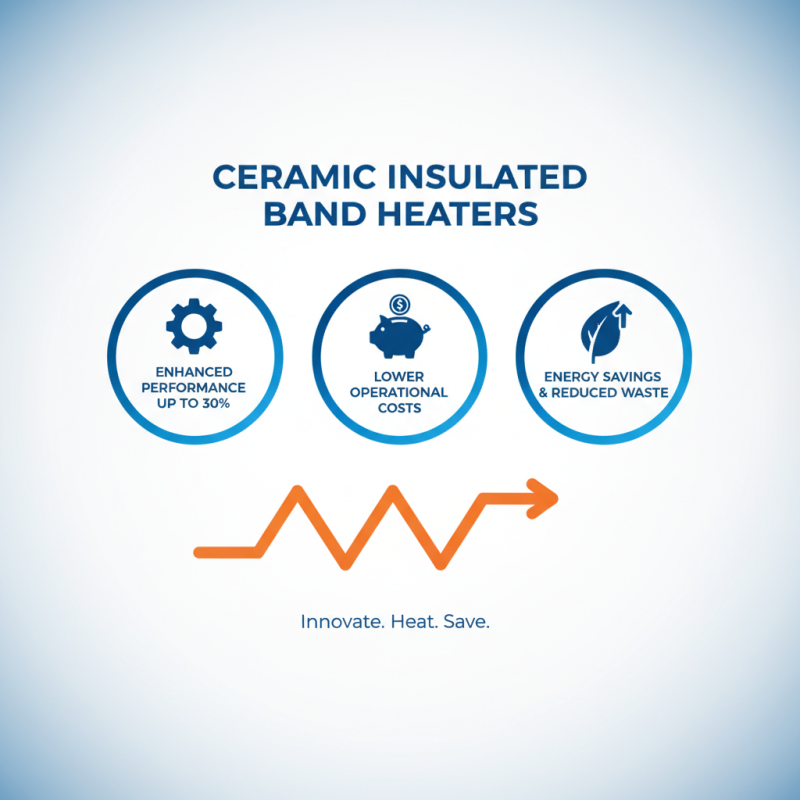

Ceramic insulated band heaters are gaining attention in various industries. Their unique design allows for efficient heating with excellent energy savings. Research indicates that these heaters can enhance performance by up to 30% compared to traditional heaters. This efficiency leads to lower operational costs and minimizes energy waste.

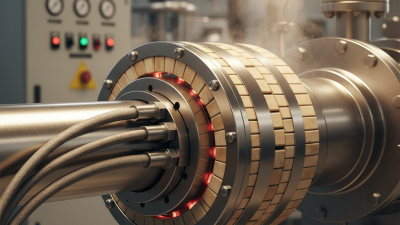

These heaters are beneficial in applications where uniform heat distribution is crucial. They can heat materials evenly, reducing hotspots. This uniformity is vital for processes requiring precise temperature control. However, users must be cautious as improper installation can lead to performance issues. The thermal insulation may not always function optimally if not fitted correctly.

While the benefits are clear, users should also reflect on their specific needs. Not all applications may require ceramic insulation. For straightforward heating tasks, traditional options might suffice. The initial investment for these advanced heaters is higher, and it could take time to realize their cost benefits. Exploring the trade-offs between efficiency and upfront costs is essential.

Ceramic insulated band heaters are becoming popular in various industries. They offer several key features that make them an ideal choice for heating processes. One standout feature is their high thermal efficiency. This helps reduce energy consumption. In an environmentally conscious world, that matters more than ever. They also provide uniform heat distribution, minimizing hot spots. This ensures that materials are heated evenly.

Additionally, ceramic insulation offers excellent durability. These heaters withstand high temperatures without degradation. They have a longer lifespan compared to traditional heating elements. Maintenance costs can be lower over time. Moreover, they are lightweight and easy to install, saving both time and labor.

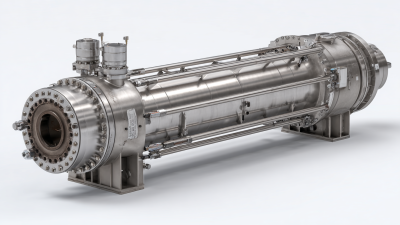

Despite these advantages, it’s important to consider some limitations. For example, they may not perform well in extremely high-pressure environments. Care must be taken to ensure compatibility with different materials. Understanding these factors can help users make informed decisions. The balance of benefits and potential downsides is essential for optimizing operational efficiency.

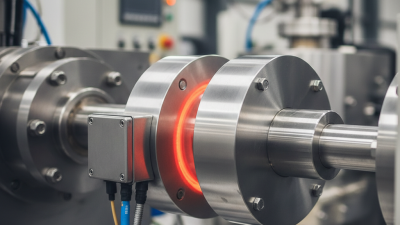

Ceramic insulation has gained popularity in industrial heating applications. One significant advantage is its excellent thermal resistance. These heaters can operate at higher temperatures without loss of efficiency. As a result, they are ideal for demanding environments.

Another benefit is energy efficiency. Ceramic materials retain heat longer, which means less energy is needed for continuous operation. This characteristic leads to cost savings over time. However, each system has limitations. The initial investment can be higher compared to traditional insulators. Businesses must assess whether the long-term benefits justify the cost.

Additionally, ceramic insulated heaters are lighter than alternatives. This characteristic simplifies installation and reduces the load on equipment. Despite these advantages, one must consider potential fragility in some types of ceramic materials. Not all facilities may benefit from ceramic insulation equally, so careful evaluation is necessary.

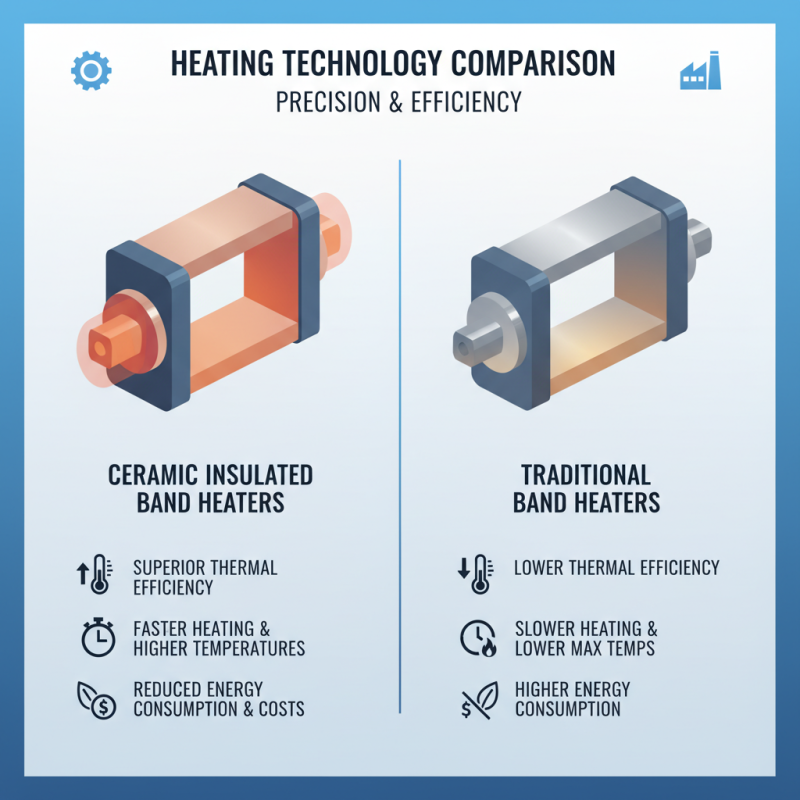

When comparing ceramic insulated band heaters to traditional ones, several key differences emerge. Ceramic heaters offer superior thermal efficiency. They can reach higher temperatures more quickly. This efficiency often results in reduced energy consumption. In industries where precision is crucial, this can be a game changer.

On the other hand, traditional insulated band heaters may provide reliability but often struggle with temperature uniformity. Their construction isn't as advanced, leading to uneven heating. Users might find themselves adjusting settings frequently. This can be time-consuming and frustrating.

Moreover, while ceramic heaters are lightweight and easy to install, traditional options can be cumbersome. Maintenance for ceramic types is often easier too. However, prices can vary greatly. Users may need to weigh these aspects carefully. Balancing cost and efficiency is essential for informed decisions.

When installing ceramic insulated band heaters, attention to detail is crucial. Ensure that the heater fits snugly around the component. Gaps can lead to inefficiency and uneven heating. Use appropriate mounting brackets for a secure fit. Proper alignment is essential for optimal performance.

Maintenance is equally important. Regularly inspect the heaters for wear or damage. Replace any worn components promptly to avoid costly downtime. Dust and debris can accumulate, affecting performance. A routine cleaning schedule will prevent build-up and improve longevity.

It's essential to adhere to the manufacturer’s guidelines for wattage and temperature settings. Going beyond these limits can lead to overheating. Reflect on your current practices and make adjustments where necessary. A proactive approach to installation and maintenance will ensure the best outcomes for ceramic band heaters.