Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

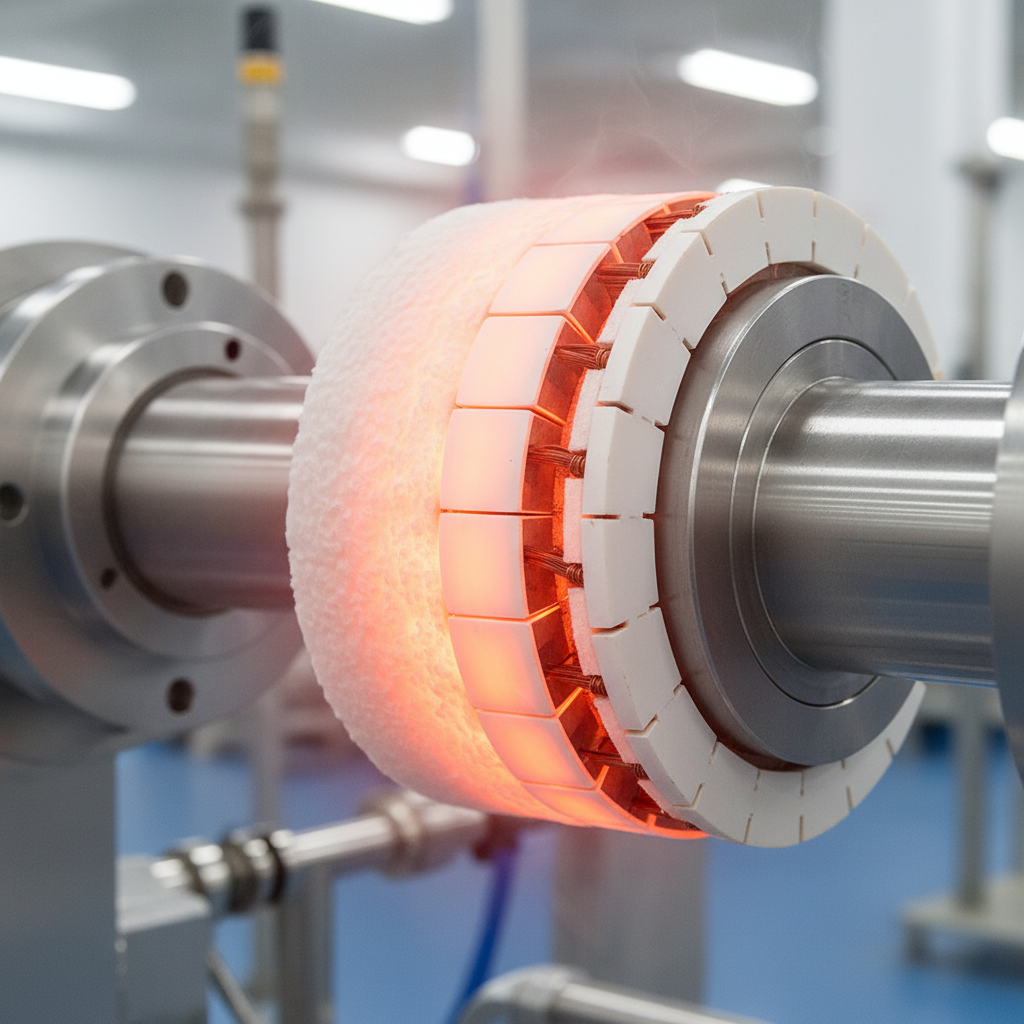

In the fast-evolving world of industrial heating solutions, understanding the intricacies of Ceramic Band Heaters is crucial for achieving optimal performance and efficiency. As an expert in the field, Dr. Emily Thompson, a leading researcher in thermal technologies, emphasizes, “The right choice and application of Ceramic Band Heaters can significantly enhance energy efficiency while ensuring precise temperature control in manufacturing processes.” This statement underlines the importance of selecting the appropriate heater type to maximize operational productivity.

As we delve into the 2025 Top Ceramic Band Heater Guide, it is essential to explore the various aspects that contribute to the effectiveness of these heating elements. From materials and construction techniques to temperature regulation and energy savings, every detail plays a vital role in driving performance. Industry professionals are continuously seeking innovative strategies that leverage the unique advantages of Ceramic Band Heaters, making this guide an indispensable resource for informed decision-making.

Through this guide, we aim to equip engineers, technicians, and facility managers with actionable insights and practical tips to enhance their applications of Ceramic Band Heaters. By doing so, we hope to foster a deeper understanding of how to harness the full potential of these exceptional heating solutions for improved efficiency and overall system reliability.

Ceramic band heaters are increasingly becoming the go-to choice for industrial applications due to their outstanding performance and efficiency. One of the top benefits of using ceramic band heaters is their superior heat distribution capability. According to a report from the Institute of Industrial Engineers, the uniform heating provided by ceramic materials can enhance temperature consistency by up to 30% compared to traditional silicone or mica-based heaters. This not only improves the quality of the product being heated but also minimizes energy consumption.

Another significant advantage lies in their resistance to thermal shock and extended lifespan. A study published in the Journal of Manufacturing Processes noted that ceramic band heaters can operate effectively at higher temperatures (up to 1,200°F or 650°C) without degrading quickly. This durability results in less frequent replacements, which can lead to substantial savings for manufacturing plants. Furthermore, the ceramic construction allows for faster thermal response times, enabling industries to ramp up production with reduced downtime.

Lastly, ceramic band heaters are designed with energy efficiency in mind, helping to lower overall operational costs. Research by Energy Star indicates that optimizing heater performance can lead to a 20% reduction in energy costs. As industries strive to be more sustainable, incorporating ceramic band heaters not only improves productivity but also aligns with energy conservation efforts.

When selecting a ceramic band heater, understanding the importance of size for optimal equipment efficiency is crucial. The size of the heater not only impacts its performance but also influences energy consumption and operational costs. A heater that is too small may not provide adequate heat, leading to uneven heating and production delays, while an oversized heater can cause overheating and increase in energy usage, which is not cost-effective.

To ensure the right fit, it is essential to measure the dimensions of your equipment accurately. This includes both the diameter and the height of the area where the heater will be installed. Additionally, consider the thermal requirements of your application. A balance between the ceramic band heater's size and the specific heat needs of your process will maximize efficiency and improve overall output. By focusing on these key factors, businesses can choose the ideal ceramic band heater that meets their operational demands while minimizing energy waste.

| Model | Size (inches) | Power Rating (W) | Temperature Range (°F) | Material | Efficiency Rating |

|---|---|---|---|---|---|

| Model A | 2.5 | 500 | 100 - 400 | Ceramic | 85% |

| Model B | 3.0 | 750 | 150 - 450 | Alumina | 90% |

| Model C | 4.0 | 1000 | 200 - 500 | Silicon Carbide | 88% |

When selecting ceramic band heaters, it's essential to consider three key factors that significantly influence their performance: temperature uniformity, insulation quality, and watt density. Temperature uniformity refers to the ability of the heater to maintain consistent temperatures across the heating surface. A heater that can provide even heat distribution helps prevent hot spots that may lead to material degradation or uneven processing. This factor becomes crucial in industrial applications where precision is vital.

Another essential aspect is the insulation quality of the ceramic band heater. High-quality insulation minimizes heat loss, improving energy efficiency and reducing operational costs. Well-insulated heaters allow for faster warm-up times and maintain the desired temperature with less energy input. Moreover, insulation contributes to the longevity of the heating element, ultimately reducing replacement costs over time.

Finally, watt density plays a pivotal role in how effectively a heater can perform under specific conditions. It refers to the amount of power applied per unit area of the heater. Selecting the correct watt density ensures that the heater can reach and maintain optimal temperatures without risking overheating or damage to the materials being processed. Careful assessment of these three factors will lead to the selection of an ideal ceramic band heater for achieving optimal performance and efficiency.

When it comes to maximizing the effectiveness of ceramic band heaters, proper installation is crucial. According to the Journal of Industrial Heating, improper installation can lead to a loss of up to 20% in energy efficiency. Therefore, ensuring a snug fit around the heated object is essential. This not only promotes optimal heat transfer but also minimizes energy wastage, allowing the heater to operate at peak performance.

Another critical factor is the alignment of the heater with the object it’s meant to heat. Industry research published by the Thermal Processing Association highlights that misalignment can cause uneven heating, which may result in product defects. To counter this, operators should regularly check and maintain alignment during installation and throughout the heater's service life. Additionally, using thermal insulation can further enhance efficiency, as it reduces heat loss and helps maintain optimal temperatures, leading to improved energy savings and extended equipment lifespan.

When it comes to maximizing the performance and efficiency of ceramic band heaters, maintenance plays a crucial role. Regular inspections and cleaning can significantly extend the lifespan of these heaters. According to a report by the Industrial Heating Equipment Association (IHEA), proper maintenance can improve energy efficiency by up to 30%, which directly impacts operational costs and sustainability objectives. Ensuring that the heater surfaces are clean and free from debris prevents hotspots and extends heating uniformity, resulting in better product quality.

Another best practice involves monitoring electrical connections and insulation integrity. A 2022 study published in the Journal of Applied Thermal Engineering indicated that nearly 25% of energy loss in industrial heating systems is due to poor insulation and electrical issues. Therefore, routinely checking these components not only reduces energy wastage but also enhances safety. Additionally, it is essential to follow manufacturer guidelines for temperature settings and near-identical heating profiles to ensure that the ceramic band heaters operate under optimal conditions, further enhancing their longevity and performance efficiency.